Waste isn’t just an inconvenient byproduct in the beverage industry – it’s a critical component in business that has an impact on compliance, brand reputation, and our mother earth.

The waste generated by the beverage industry makes up 26% of food waste. Considering that the US generates around 106 million tons of food waste every year, this is a staggering number that calls for attention.

With sustainable practices becoming the norm, the beverage industry is facing more and more scrutiny from both consumers and regulators. While steps are being taken towards better waste management in the food and beverage industry, the problem still persists.

Manufacturers and distributors have to deal with different types of waste, including packaging and liquid byproducts, requiring custom strategies for long-term waste reduction.

In this guide, we explore the key challenges of managing beverage industry waste, what regulations you need to stay compliant with, why non-alcoholic beverages require specialized destruction, the beverage disposal process and chain of custody, and much more.

Key Takeaways

- Beverage manufacturers face unique waste challenges, from high-volume liquid disposal to complex multi-layer packaging recycling and strict segregation requirements.

- A strong strategy combines smarter treatment technologies, recyclable and reusable packaging, and proactive compliance monitoring to reduce risk and environmental impact.

- Because regulations and documentation requirements span agencies like the FDA, TTB, and EPA, traceability and chain-of-custody records are essential for audit readiness and long-term compliance.

- Non-alcoholic beverages often require specialized destruction and disposal processes based on their ingredients and packaging, making tailored compliance essential to reduce risk and maximize landfill diversion.

- The beverage disposal process follows four critical steps (collection, transportation, verified destruction, and documentation), each requiring strict chain-of-custody controls to ensure compliance and traceability.

Understanding Waste Management in the Beverage Industry

Beverage waste is about more than just empty cans or bottles. Beverage manufacturing and distribution produce a huge variety of waste streams, including:

- Liquid waste, such as expired drinks and production byproducts

- Packaging materials like plastic bottles and aluminum cans

- Sensitive or hazardous substances like alcohol

Handling all this waste in a proper way isn’t just good practice. Instead, it’s crucial if you want to stay compliant and sustainable while running a successful operation.

The beverage industry produces waste that has particularly complex recycling or destruction methods. That’s why managing liquid food and beverage waste requires intricate beverage destruction strategies.

5 Key Challenges in Waste Management for the Beverage Industry

Waste management in the food and beverage industry is far from simple. Manufacturers and distributors face tons of issues, like having to manage massive volumes of liquid waste and staying compliant with complicated recycling processes.

We’ve identified the 5 biggest challenges that beverage manufacturers have to overcome to be able to effectively and sustainably manage beverage waste. Let’s talk about them.

1. Managing High-Volume Liquid Waste

One of the toughest challenges for beverage producers is the sheer amount of liquid waste they need to handle. Liquid waste disposal covers things like:

- Expired soda

- Contaminated juices

- Huge volumes of rinse water

- Spills

- Much more

Getting rid of such waste in an ethical and sustainable way takes meticulous planning. If you want to mitigate these challenges, avoid causing harm to the environment, and steer clear of regulatory headaches, you need to learn all about effective beverage destruction management.

2. Complexities in Recycling Multi-Layer Packaging

Beverage packaging often involves multi-layer materials like Tetra Paks. The combination of plastic, paper, and aluminum layers makes it notoriously hard to recycle packaging materials in the beverage industry.

Aside from being hard to deal with, these packaging materials are also expensive to recycle, which creates a challenge for businesses to find innovative, sustainable solutions.

Fun fact: Nestlé generated more than 1.5 million metric tons worth of waste in 2023.

3. Compliance with Environmental Regulations

Waste management in the beverage industry is super complicated in terms of compliance as well. Governments impose stringent environmental regulations upon beverage manufacturers, especially when it comes to potentially hazardous liquid waste like alcohol.

If you fail to follow beverage waste compliance standards, it won’t just cost you financially; it will cost you in terms of your brand reputation and more.

4. Reducing Single-Use Plastic Dependency

Plastic packaging dominates the beverage market, yet environmental backlash and regulatory bans on single-use plastics continue to rise higher and higher.

To meet the new demands of waste management in the beverage industry, manufacturers have to simply embrace alternatives or risk being sidelined by both consumers and regulators.

5. Implementing Effective Waste Segregation Systems

Last but not least, let’s talk about waste segregation systems. They have a huge impact on your recycling programs. So, manufacturers have to make sure to have:

- Clearly marked bins

- Regular staff training

- Strict operational guidelines

This is just the bare minimum in terms of handling hazardous materials and recyclables safely and effectively. It is the producer’s responsibility to properly separate recyclable materials from general waste, ultimately enhancing recycling rates and reducing landfill contributions.

9 Strategies for Effective Waste Management in the Beverage Industry

When your waste management strategy is robust, compliance becomes effortless. Yes, you will need strategic thinking, innovative technology, and proactive planning, but it will all be worth it.

Smarter liquid waste treatments, redesigning packaging for recyclability, and embracing reusable solutions are just some of the ways beverage manufacturers can improve compliance, reduce environmental impact, and more.

Let’s talk about some proven strategies that can help you get there.m general waste, ultimately enhancing recycling rates and reducing landfill contributions.

1. Adopting Advanced Liquid Waste Treatment Technologies

One of the most impactful ways beverage producers can handle liquid waste is through advanced treatment technologies like anaerobic digestion.

This process doesn’t just dispose of waste – it turns liquid byproducts into renewable biogas or nutrient-rich fertilizers. It is truly a high-standard solution in the world of managing beverage waste, which is why many liquid waste disposal services use this technology.

Another strategy for waste management in the beverage industry is using membrane bioreactors. Both of these methods help your production stay compliant with environmental regulations. The cherry on top is that they also give you opportunities to recover energy and reuse water.

2. Redesigning Packaging for Enhanced Recyclability

Forward-thinking beverage companies are making a shift toward mono-material packaging and biodegradable materials to make recycling easier. They choose packaging that is easier to recycle from the get-go, thereby significantly decreasing their environmental impact and meeting the standards of consumers who demand sustainability.

With proactive packaging redesign, companies don’t just reduce waste – they take their brand perception to another level and bring in long-term customer loyalty.

3. Implementing Robust Compliance Monitoring Systems

Beverage waste compliance isn’t just paperwork – it’s peace of mind. As a manufacturer, it’s your responsibility to establish compliance teams and use smart software to stay ahead of ever-evolving environmental regulations.

Luckily, we’re living in a world where AI and automation tools can flag issues early on, helping you prevent expensive fines and legal messes. As a bonus, you also promote your brand’s corporate responsibility.

Quick tip: Companies proactive in compliance management spend less time and resources on audits and penalties.

4. Investing in Reusable Packaging Solutions

Imagine packaging that never hits the trash. Reusable packaging is the future, which is why forward-thinking beverage companies are adopting solutions like refillable bottles, growlers, and bulk dispensers.

All of this drastically reduces reliance on single-use plastic. The benefits are immediate:

- Reduced costs

- Smaller environmental footprints

- Increased consumer loyalty

Fun fact: Refillable beer kegs (15.5 gallons) can replace 165 (12-ounce) single-use bottles, helping brands save money and write powerful brand stories.

5. Developing Comprehensive Waste Segregation Protocols

Successful waste management starts on the facility floor. With clearly defined and enforced waste segregation guidelines, employee training, clear visual labeling, and proper beverage waste storage, manufacturers can ensure that recyclables end up recycled – not wasted.

Waste management in the beverage industry has distinct segregation protocols, which are especially important for things like expired beer recycling and proper wine disposal.

6. Meeting Compliance and Traceability Standards Through Waste Management

Regulations in the beverage industry aren’t getting any looser. If anything, the bar is rising. Staying compliant isn’t only about avoiding fines but also about building a traceable, trustworthy system that protects your brand and proves you’re doing things right.

Complying with standards for waste management in the food and beverage industry is intricate, involving Certificates of Destruction, adherence to government regulations, and constant audit readiness, as we discuss below.

7. Certificates of Destruction and Documentation

Proof matters. In the world of waste management, formal documentation has tons of value. For example, Certificates of Destruction show verifiable records that you handle your waste responsibly both internally and externally.

Ultimately, this protects your brand and satisfies your regulators. If you’re still unsure how all of this works, partnering with beverage destruction companies can help.

8. Support for Government and Industry Regulations

The destruction and recycling of unsaleable beverages must meet the strict requirements of regulatory bodies like:

- Tax and Trade Bureau (TTB)

- Department of Homeland Security

- U.S. Customs (in some cases)

Whether you’re dealing with packaging waste or the disposal of alcohol-based beverages, specialized waste partners can help you navigate and meet every requirement with confidence.

9. Audit Readiness and Supply Chain Transparency

From recalled beverage disposal to non-alcoholic beverage destruction, traceable waste handling builds trust across your supply chain. With organized records and clear reports, you will always be prepared for audits, stakeholder reviews, and even product recalls. .

Key Operational Benefits of Structured Beverage Destruction Services

Beverage destruction isn’t just about getting rid of products you can no longer sell – it’s about doing it efficiently, securely, and sustainably. Doing it on your own can be extremely tough, which is why you should turn to a reliable beverage destruction service.

The right partner can bring in real operational value, protect your brand, bottom line, and even environmental commitments through the following benefits.

1. Minimized Operational Disruption

Structured destruction services shouldn’t disrupt your schedule – they should be designed to work around it. Ideally, your partner should organize fast pickups and streamlined logistics so that your team can steer clear of bottlenecks when managing unsaleable or excess inventory.

2. Secure and Compliant Disposal Chain

When you work with professionals, you can rest easy knowing that every step from pickup to final processing is documented and traceable. It’s no secret that a secure chain of custody and eco-friendly routing are essential for modern beverage waste handling.

3. National Reach for Scalable Solutions

Whether you operate one facility or fifty, a nationwide service network ensures consistency across locations. That means you can expect:

- Uniform standards

- Centralized tracking

- Simplified vendor management

With a broad network of vetted processing facilities, your business can scale its waste destruction needs across regions easily and quickly.

4. Eco-Friendly Repurposing and Recycling

Destruction doesn’t mean waste – it can mean recovery, which is key to successful waste management in the beverage industry.

Whether it’s beer keg decanting or packaging recycling, structured beverage destruction services can repurpose your waste into energy or raw materials, supporting circular economy goals and reducing landfill usage.

5. Taceability and Documentation

Do you have an audit, compliance check, or internal report coming up?

With a reliable partner, you won’t have to worry about any of it. You’ll have comprehensive documentation for every load destroyed, including the paperwork and proof you need to stay inspection-ready.

Beverage Disposal Process & Chain of Custody

We’ve broken down the beverage disposal process into four key steps:

Step 1 – Collection & Segregation

The first step in beverage disposal is the collection and segregation of waste. Your waste collection partner performs an initial product assessment and volume verification to ensure the disposal strategy aligns with your specific waste requirements.

An important part of this process is product segregation to prevent cross-contamination, especially during recalled beverage disposal. Clear protocols should be implemented both at your facility and by the waste management partner during collection and transport.

For your company, this may involve training employees to properly handle and separate waste, providing clearly labeled bins for beverage waste storage, and maintaining accurate waste logs.

For an experienced beverage destruction company, this means following established chain-of-custody procedures, using dedicated collection methods, and ensuring materials remain properly identified, segregated, and documented throughout the disposal process.

Step 2 – Transportation

Next, the beverage waste must be transported to a processing facility. Your waste management partner must follow all applicable legal and regulatory protocols, as requirements for waste handling and transportation vary by waste type and state.

During transport, a Bill of Lading is used to document the shipment. This legal document records key details such as the type of waste, quantities transported, origin, destination, and chain-of-custody information, helping ensure traceability, compliance, and accountability throughout the disposal process.

Step 3 – Verified Destruction

The next step: destruction.

This process varies depending on your waste type and agreed disposal method. That said, the priority should always be safe disposal. By following EPA-compliant destruction methods, companies can reduce their environmental footprint and achieve their sustainability goals.

Verified destruction also includes documented proof, such as destruction reports or Certificates of Destruction, which confirm materials were permanently destroyed and removed from the supply chain.

Step 4 – Documentation & Compliance

Proper documentation is non-negotiable, regardless of product type or disposal method.

Comprehensive records help ensure beverage waste compliance and keep your organization inspection-ready. While documentation requirements can vary by product type, waste classification, and jurisdiction, maintaining a clear and complete audit trail is essential.

These records include beverage destruction metrics such as volume destroyed, destruction method used, and compliance verification status, all essential for audit readiness and regulatory reporting.

For example, non-alcoholic beverage destruction typically requires core chain-of-custody documentation, such as timestamped intake logs, weighbridge entries, and before-and-after photo evidence, to verify proper handling and final disposition.

Regulatory Compliance in Beverage Disposal

Your waste management partner should stay up to date on all applicable regulatory requirements and help keep you informed and compliant as regulations evolve.

That said, here’s a quick overview of what you need to know.

1. FDA Requirements

While the FDA does not directly regulate beverage waste disposal, it does oversee food recalls. The FDA requires proper documentation of recalled products to evaluate, classify, monitor, and audit product recalls.

In many cases, this includes records showing that recalled beverages were properly disposed of or destroyed to ensure they cannot re-enter the marketplace.

The FDA also regulates juice safety through the Juice HACCP rule, which applies to all juice sold as juice or used as an ingredient in other beverages, except juice produced at retail establishments. Under this regulation, juice processors must develop and implement HACCP plans to identify and control potential biological, chemical, and physical hazards.

To support traceability and accountability, the FDA also requires both manufacturers and retailers to maintain records of food receipt and release in accordance with sections 1.337 and 1.345.

2. TTB Beverage & Alcohol Compliance

For alcoholic beverages, disposal and destruction are subject to oversight by the Alcohol and Tobacco Tax and Trade Bureau (TTB). When alcohol is destroyed rather than sold, TTB regulations may require documentation to verify the quantity destroyed and support compliance with federal alcohol laws and tax requirements.

Under the Code of Federal Regulations, an application may be required before destroying wine, beer, or spirits. This application typically includes:

- Alcohol type

- Alcohol content

- Approximate volume to be destroyed

- Where the alcohol will be destroyed

- Reason for destruction

Unless the TTB authorizes that inspection and supervision are not required, the alcohol must be inspected, the destruction must be supervised, and all records must be maintained.

It’s important to note that destruction must also comply with local environmental and waste disposal rules, not only federal alcohol laws.

Working with a beverage destruction company that understands the regulations tied to your location and operations helps ensure alcohol is handled in accordance with TTB requirements while maintaining accurate records for beverage waste compliance, reporting, and potential audits.

3. EPA Environmental Regulations

The United States Environmental Protection Agency (EPA) regulates household, industrial, and manufacturing solid and hazardous wastes under the Resource Conservation and Recovery Act (RCRA). The EPA also sets wastewater discharge limits under the Clean Water Act, which can impact how beverage waste, especially liquids, is destroyed and discharged.

Beyond liquid disposal, packaging waste also comes with its own handling and recycling requirements. Common recyclables such as plastics, glass, and aluminum must be properly separated and routed through the correct waste stream to support sustainability efforts.

For example, since some plastics aren’t accepted in community recycling programs, it’s important to confirm what your local program allows.

With regulations spanning the FDA, TTB, and EPA, navigating beverage destruction without proper compliance can lead to penalties, environmental violations, failed audits, and reputational damage. That’s why it’s important to understand how to choose a beverage destruction company that truly supports your goals.

Non-Alcoholic Beverage Waste Management

While the disposal process and regulatory framework apply broadly across beverage types, non-alcoholic beverages present unique challenges that require specialized destruction approaches.

Let’s explore why.

Why Non-Alcoholic Beverages Require Specialized Destruction

Due to their unique product characteristics, non-alcoholic beverages fall under different regulations compared to alcoholic beverages. Why?

Because products like energy drinks, juice, and water all have different disposal triggers than alcohol. This includes:

- Sugar density → impacts effluent load limits

- Carbonation → affects rupture and pressure-release thresholds

- Vitamin/functional additives → influence disposal routing

- Shelf-life instability → requires faster liquidation windows

Understanding the differences between compliance requirements becomes even more complicated for companies that have multiple types of products and packaging. This is because it’s impossible to group all non-alcoholic beverages into a single category.

From aluminum cans to plastic bottles and sustainable beverage packaging, each material requires specialized handling to ensure compliance and maximize landfill diversion.

Technical Composition Factors

To truly understand non-alcoholic beverage destruction, we need to take a look at the technical composition of these products.

1. Composition Considerations

Non-alcoholic beverages typically carry destruction requirements tied to ingredient density rather than alcohol content. For instance, many include additives like taurine, vitamin blends, and caffeine concentrates. Others contain high-sugar formulations, electrolyte fortification, or flavor emulsions that increase the biochemical load and further narrow downstream routing options.

Because of these factors, their compositions often exceed anaerobic digestion thresholds and create effluent classification challenges. In other words, eligibility cannot be assumed based on liquid state alone, which directly influences the appropriate beverage destruction method.

2. Degradation Requirements

Because non-alcoholic products degrade faster and ferment differently than spirits, their recall windows and storage tolerances are significantly shorter. Certain product categories, like energy drinks, fortified juices, and vitamin waters, also need early-stage analytical screening to determine whether landfill diversion, aerobic digestion, or depackaging recovery is appropriate.

At Shapiro, we provide certified recall, disposal & beverage destruction services that account for these faster degradation cycles, ensuring each product is routed to a compliant and suitable end-of-life solution.

3. Carbonation & Pressurization Handling

Carbonated drinks come with hazards that other beverages simply don’t, especially pressurization risks.

Because energy drinks and sparkling juices contain trapped CO₂, they’re more prone to rupturing under pallet compression, compaction, or during transport. To mitigate these risks, operations rely on depressurization sequencing, controlled venting, and proper shrink-wrap tension.

As a result, handling protocols prioritize failure prevention over recyclability. These safety measures can also slow throughput, since pressurized SKUs require longer clearance intervals during destruction.

High-Volume Disposal Challenges

Non-alcoholic beverages move quickly through the supply chain, creating disposal challenges such as:

- Perishability: Perishability is a huge issue in the beverage industry. Challenges include products expiring faster than anticipated, demand forecasts missing the mark, and sudden waves of unsellable beverage waste piling up in storage—all of which pose food and beverage safety concerns when not managed quickly.

- Cold-storage overload: Cold-storage overload can happen quickly in high-volume operations. Limited refrigeration space, unexpected inventory spikes, or cold-chain breakdowns can all lead to rapid spoilage and immediate disposal needs.

- Promotional overproduction & SKU churn: Promotional cycles often create more inventory than the market can absorb. Seasonal flavors, limited-time SKUs, and short-lived campaigns can leave companies with excess stock that must be sorted, stored, and destroyed.

- Labeling errors: Labeling mistakes are another common challenge in beverage production. Misprints related to caffeine content or ingredients can trigger recalls, regulatory intervention, and mandatory destruction of affected batches.

- Additive destabilization: Functional beverages are especially susceptible to ingredient instability. Temperature fluctuations, storage issues, or formulation changes can cause vitamins, electrolytes, or botanicals to degrade, forcing early disposal to maintain safety and quality.

All this to say, the beverage industry faces unique challenges that often lead to surplus products that must be destroyed. Because these excess volumes aren’t always accounted for in a company’s waste management plan, it’s critical to have a disposal partner capable of handling sudden surges in beverage destruction needs.

Chain-of-Custody Documentation for Non-Alcoholic Beverages

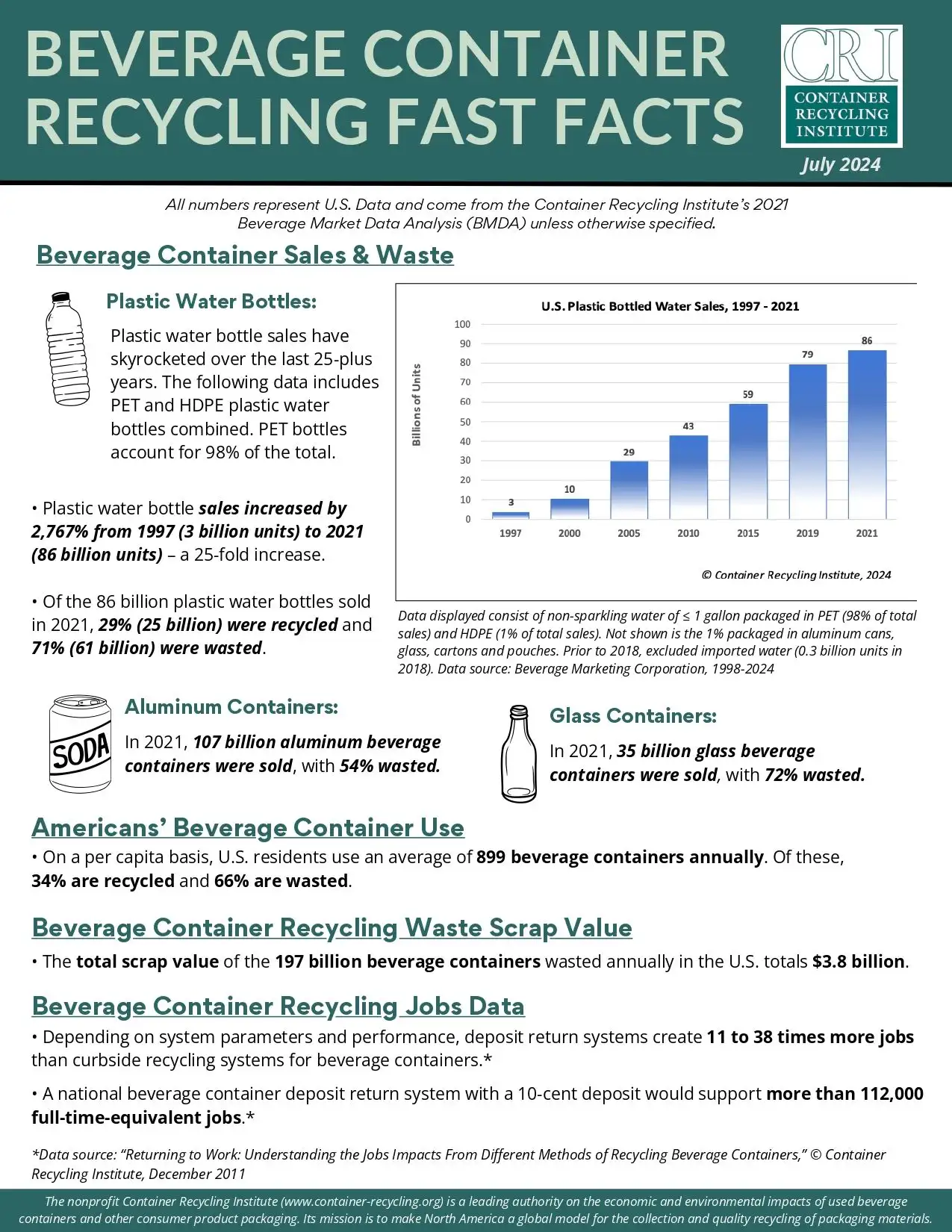

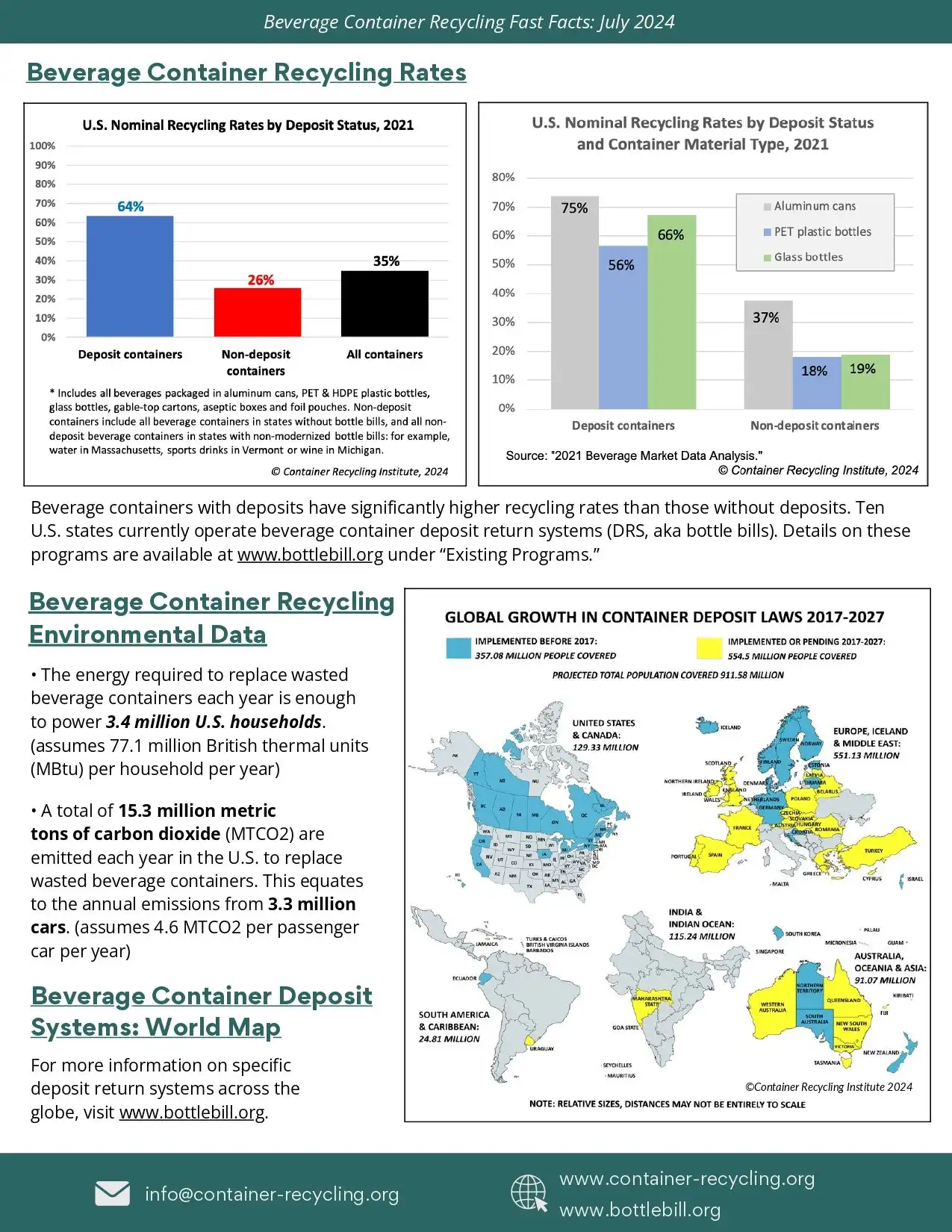

Source: CRI

Curious about chain-of-custody documentation?

Here’s what you need to know:

What Chain-of-Custody Documentation Includes

So what can you expect to see in proper chain-of-custody records?

Here are the core documents typically involved:

- Sealed trailer identification numbers

- Pallets labeled with SKU codes

- Timestamped intake logs

- Weighbridge entries

- Before-and-after photo evidence

- A Certificate of Destruction

Documentation Timelines & Delivery

When dealing with beverage destruction, timing is critical due to the shelf-life instability and carbonation risk of many liquid products. Because these beverages can change rapidly in composition or stability, the certification process must move quickly to ensure documentation accurately reflects the product’s condition at the moment of destruction.

This expedited flow helps maintain compliance, supports brand protection, and ensures all stakeholders receive timely confirmation.

It also ensures beverage destruction documentation stays reliable, accurate, and aligned with the product’s short viability window.

Non-Alcoholic vs. Alcoholic Documentation Differences

Beverages such as juices, energy drinks, and vitamin water present unique challenges, including shorter shelf lives, carbonation instability, complex additive profiles, and warehouse space constraints. As a result, they typically require more frequent and precise documentation than spirits.

For companies focused on compliance, accurate and timely documentation shouldn’t be an afterthought. Instead, it should be a core component of an effective waste management strategy.

At Shapiro, we understand the importance of staying up-to-date with documentation and implementing strategies that support both compliance and sustainability. With expert insight into beverage destruction, we help streamline the entire process.

Conclusion

Effective waste management in the beverage industry isn’t about avoiding fees or fulfilling your obligation; it’s an opportunity to strengthen compliance, become more sustainable, and boost your operational efficiency.

There will be challenges along the way, but if you address them proactively, your business will be able to preserve its reputation, satisfy the expectations of consumers, and stay ahead of ever-shifting regulations.

If you’re a beverage manufacturer, distributor, or sustainability leader, we recommend taking a closer look at your current system and considering the strategies outlined above.

From following proper disposal processes and chain-of-custody protocols to handling non-alcoholic beverage waste and staying compliant with juice and spirits regulations, the right approach should be tailored to your company.

Ready to partner with a full-scale beverage destruction provider like Shapiro?

Don’t hesitate to get in touch. Our team is always ready to deliver customized support.

FAQs about Beverage Waste Management

Beverage waste management helps manufacturers comply with regulations, reduce the impact they leave on the environment, cut their disposal costs, and protect their reputations. If done right – it can also support sustainability goals and make them even more efficient.

Beverage waste is more than just bottles and cans. It also includes expired drinks, leftover liquids from production, broken packaging, plastic shrink wrap, and even regulated products like alcohol that need special handling.

Think of beverage destruction as the safety net for everything you can’t sell. It makes sure your products or byproducts are disposed of securely, legally, and responsibly so that they don’t end up in the wrong hands or harm the environment.

Beverage waste tends to be liquid-heavy and often includes alcohol, which means stricter regulations and different disposal needs. It’s not as simple as composting leftovers – it requires a plan and a partner who knows the rules.

If beverage disposal is not properly documented, companies may face compliance issues, failed audits, regulatory penalties, and increased risk of reputational damage due to the inability to prove that products were properly destroyed and removed from commerce.

Both parties share responsibility, but the brand ultimately remains accountable for disposal compliance. While the disposal vendor is responsible for following proper handling, transportation, and destruction procedures, the brand must ensure the vendor is qualified, compliant, and provides proper documentation to verify that disposal was completed correctly.

Yes. Regulatory and facility-specific limits are used to determine whether beverage waste is eligible for anaerobic digestion or must be routed to landfill.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.