Sustainability is taking center stage in the beer brewing industry, with many recognizing its critical role in preserving our environment. Choosing the right beer keg is a significant decision that directly influences a brewery’s ecological footprint. Traditional methods of beer packaging and distribution often overlook the long-term environmental impacts. However, a shift in mindset is occurring, as more breweries are now seeking sustainable alternatives.

By considering the environmental implications of different types of beer kegs, breweries can contribute to a healthier planet while still delivering quality beer to their consumers.

Let’s take a magnified look at the various keg options and how they align with sustainable practices in the brewing industry.

Key Takeaways

- Stainless steel kegs, known for their durability and recyclability, significantly reduce waste and energy consumption over their lifecycle compared to less durable alternatives, making them a sustainable choice for breweries committed to environmental stewardship.

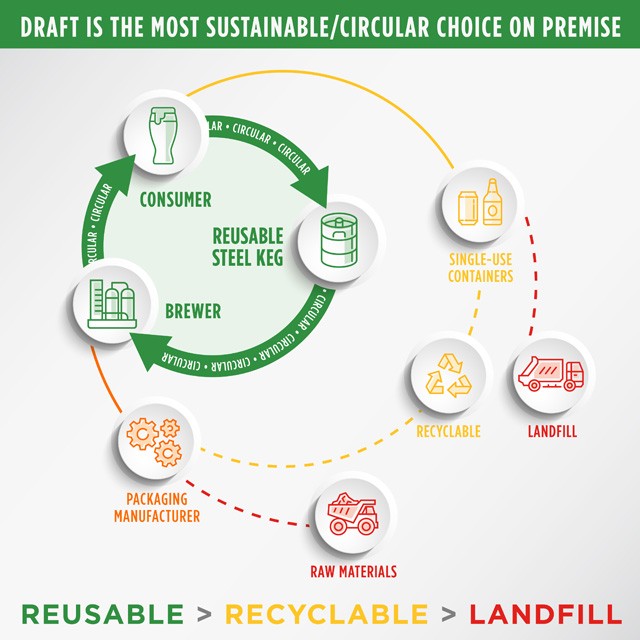

- Implementing a keg return and refill program can dramatically cut down on waste and carbon footprint, as reusing kegs eliminates the need for constant production and disposal of single-use containers, thereby aligning brewery operations with sustainable practices.

- Collaboration between breweries, keg suppliers, and recycling programs is essential for fostering a circular economy in the brewing industry, where kegs are continuously reused, repurposed, or recycled, minimizing environmental impact and promoting sustainable resource utilization.

Understanding Different Beer Keg Types

First, we need to answer the question, “What are beer kegs made of?” This is because various aspects such as the material, style, and lock type play an important role in how long a keg lasts and what sustainability implications they may have.

Stainless Steel Kegs

Stainless steel kegs stand out for their reusability and long-term durability, presenting an excellent option for breweries looking to combine quality with sustainability. These kegs can endure numerous cycles of use, reducing the need for frequent replacements and contributing to waste reduction. When they do eventually wear out, their materials are recyclable, offering a responsible end-of-life option.

- Use Frequency: Widely used across the industry due to their durability.

- Sustainability: Highly sustainable due to their reusability and recyclability.

- Durability: Extremely durable, resistant to corrosion and damage.

- Maintenance: Requires regular cleaning but is straightforward to maintain.

- Lifespan: Can last for several decades if properly maintained.

- Beer Freshness: Preserves beer freshness for extended periods.

Pros:

- Durable

- Reusable

- Recyclable

- Maintains beer quality

Cons:

- Heavier than other types of kegs

- Can be more expensive initially

Plastic Kegs

Plastic kegs, known for their lightweight nature, offer ease in handling and transportation. However, they pose challenges in recycling, and their long-term environmental impact is a consideration that breweries must weigh. The good news is that innovations are on the rise, with manufacturers working towards more sustainable plastic solutions.

- Use Frequency: Gaining popularity, especially for smaller breweries or specific markets.

- Sustainability: Less sustainable due to recycling challenges.

- Durability: Less durable than stainless steel, prone to damage.

- Maintenance: Easy to clean but may have a shorter maintenance lifespan.

- Lifespan: Generally shorter than stainless steel kegs.

- Beer Freshness: Comparable to stainless steel, though depends on the keg’s condition.

Pros:

- Lightweight

- Easy to handle

- Cost-effective for short-term use

Cons:

- Less durable,

- Recycling issues

- May have a shorter lifespan

Wooden Kegs

Wooden kegs carry a historical charm and have a unique place in the brewing world, particularly in aging select beers. These kegs are biodegradable, providing a natural end-of-life process. While they might not be the go-to solution for every brewery, they have their niche and can be a part of a brewery’s sustainable practices. Breweries opting for wooden kegs should balance their specific needs with the environmental benefits these kegs offer.

- Use Frequency: Less common today but used for specific beer types like cask ales.

- Sustainability: Biodegradable and often sourced from sustainable forestry.

- Durability: Less durable than metal alternatives, susceptible to damage.

- Maintenance: Requires careful maintenance to prevent contamination.

- Lifespan: Shorter than stainless steel, depends on care and maintenance.

- Beer Freshness: Can impact the beer’s flavor, adding unique characteristics.

Pros:

- Adds unique flavors

- Biodegradable

Cons:

- Requires careful maintenance

- Shorter lifespan

- Less common.

| Keg Type | Durability | Maintenance Needs | Typical Lifespan |

| Stainless Steel | Extremely high; resistant to corrosion and damage; withstands high pressure and harsh conditions | Regular cleaning required with standard industry cleansers; needs periodic inspection for any signs of wear and tear | Up to 30 years or even longer, depending on care and maintenance |

| Plastic | Moderate; more prone to damage and wear compared to stainless steel; sensitive to UV light and extreme temperatures | Easy to clean but may require more frequent replacements; visual inspection needed to detect any cracks or deformities | Typically, 5-10 years, depending on usage and care |

| Wooden | Lower; susceptible to damage from external elements and requires controlled storage conditions | Requires regular and meticulous cleaning to prevent contamination; needs to be kept in a controlled environment to prevent drying out or becoming waterlogged | Typically, 5-10 years, can be longer if properly maintained |

Keg Types: Styles and Sizes

| Keg Type | Style | Capacity | Material Options | Reusability | Notable Features |

| Cornelius Keg | Soda keg style | 5 gallons (18.9 L) | Stainless steel | Reusable | Popular for homebrewing, easy to clean and fill |

| Mini Keg | Small, portable | 1.32 gallons (5 L) | Steel, aluminium | Limited reuse | Compact size, perfect for small gatherings |

| Beer Ball | Spherical | 5.23 gallons (19.8 L) | Plastic | Single use | Lightweight, easy to transport |

| One-Way Kegs | Various (like standard kegs) | Varies | Plastic | Single use | Lightweight, recyclable, no return logistics needed |

| Half Barrel Keg | Standard keg | 15.5 gallons (58.7 L) | Stainless steel | Reusable | Commonly used in commercial brewing |

| Quarter Barrel Keg (Pony Keg) | Short and stout | 7.75 gallons (29.3 L) | Stainless steel | Reusable | Smaller version of the half barrel, easier to handle |

| Slim Quarter Keg | Tall and slim | 7.75 gallons (29.3 L) | Stainless steel | Reusable | Space-saving design, fits in smaller spaces |

| Sixth Barrel | Like slim quarter | 5.16 gallons (19.5 L) | Stainless steel | Reusable | Smaller volume, growing in popularity |

| Eighth Barrel | Smaller version of sixth barrel | 3.875 gallons (14.7 L) | Stainless steel | Reusable | Ideal for small batch brewing |

The Environmental Impact of Keg Choice

Pioneering sustainability in brewing requires a critical evaluation of the entire lifecycle of kegs. This involves a nuanced understanding of their carbon footprint, an appreciation for the virtues of durability, and a strategic approach to recyclability and reusability. Let’s dissect these elements to paint a comprehensive picture of sustainability in the keg selection process.

Carbon Footprint: Production and Transportation

Stainless steel kegs, while durable and recyclable, require a substantial amount of energy for production, contributing to a higher initial carbon footprint. However, their long lifespan can mitigate this impact over time.

On the other hand, plastic kegs have a lower production carbon footprint due to their lighter materials, but their recycling challenges and shorter lifespan might offset these initial benefits.

Wooden kegs, while biodegradable, can be heavy and cumbersome to transport, potentially leading to higher emissions during distribution.

Durability and Lifespan: The Longevity Factor

Durable materials like stainless steel offer extended use, making them a more sustainable option in the long run. Kegs that withstand wear and tear reduce the need for frequent replacements, ultimately leading to less waste and a smaller environmental footprint. While plastic and wooden kegs might not offer the same longevity, their other sustainable features can still make them viable options, depending on the brewery’s specific needs.

Recyclability: End-of-Life Options

Stainless steel shines in this regard, as it is fully recyclable, ensuring that materials are not wasted when the keg is no longer usable. Plastic kegs, while challenging to recycle, are seeing improvements with advancements in materials and recycling processes. Wooden kegs, though not recyclable in the traditional sense, offer biodegradability, returning to the earth without contributing to landfill waste.

Reusability: Embracing Return and Refill Programs

Reusability is a cornerstone of sustainable practices, and keg return and refill programs play a crucial role in this. Breweries that implement and promote these programs encourage a circular economy where kegs are continuously reused, minimizing waste and reducing the need for new kegs. This practice is essential in driving the industry towards more sustainable operations.

Choosing the Right Keg for Your Brewery

The right type of keg isn’t just a matter of sustainability; it’s also a strategic business decision that influences operations, branding, and bottom lines. Here’s a breakdown of the critical aspects’ breweries must weigh:

Size and Volume Considerations

Choosing the right size and volume of kegs directly correlates with a brewery’s production scale and market demand. Smaller kegs may be apt for limited edition brews or smaller-scale distribution, ensuring less product waste and better turnover. Conversely, larger kegs could be more efficient for breweries with higher output or well-established distribution channels, offering economies of scale. Each brewery must assess their volume needs carefully to optimize supply and minimize surplus.

Transportation and Distribution

The type of keg a brewery uses can significantly sway transportation emissions. Heavier kegs like those made of stainless-steel increase fuel consumption during shipping, whereas lighter plastic kegs can trim down the carbon footprint. However, the bigger picture includes the distance of distribution channels and the keg’s return journey for refilling—factors that could nullify the benefits of lighter kegs if logistics aren’t managed with an eye for efficiency.

Cost Analysis

While initial costs are a tangible factor in decision-making, breweries must also consider the long-term sustainability benefits of their keg choices. Stainless steel kegs, though costlier upfront, could prove more economical over years of use, thanks to their durability and the minimal need for replacement. Plastic kegs may offer a lower initial investment but could incur higher costs in the long run if they require more frequent replacement due to lower durability.

Brand Image

A brewery’s keg choice is a statement of their brand’s values. Opting for more sustainable types of beer kegs can bolster a brewery’s image as an environmentally conscious brand. It’s crucial for breweries to align their keg selections with their sustainability goals to maintain authenticity in their brand image. This alignment not only attracts consumers who value eco-friendly practices but also instills a sense of purpose and responsibility within the brand’s ethos.

Best Practices for Sustainable Keg Management

Maintenance Tips for Keg Longevity:

Proactive Cleaning:

Regular cleaning isn’t only about hygiene; it’s an investment in your kegs’ longevity. Utilizing eco-friendly cleaners, brewers can ensure their kegs are ready for the next batch without contributing negatively to the environment.

Thorough Inspection:

Keeping a keen eye on your kegs can prevent minor issues from becoming major problems. An inspection routine can help identify signs of wear and tear early, keeping your kegs in service longer and reducing waste.

Proper Storage:

A keg treated well is a keg that lasts. Storing beer kegs in a controlled environment shields them from the elements and can prevent premature aging.

Gentle Handling:

Each keg should be handled with care to avoid dents and damage that can compromise its integrity. Educating staff on proper handling techniques is an effective way to ensure your kegs’ durability.

Timely Repairs:

Addressing small issues promptly can extend a keg’s functional life dramatically. Having a relationship with a reputable repair service can be beneficial.

It’s important to note that, when discussing sustainable practices, alcohol disposal is a key aspect. Breweries must have proper protocols in place for disposing of alcohol that can’t be sold, ensuring that this process is done responsibly and in an environmentally friendly manner.

Engagement in Recycling Programs:

By engaging with keg and beer recycling programs, breweries can ensure their containers live on, even after reaching the end of their beer-holding days. This is where cooperation with recycling initiatives can be a huge win-win.

Strategic Collaborations:

It’s important to note that, when discussing sustainable practices, alcohol disposal is a key aspect. Breweries must have proper protocols in place for disposing of alcohol that can’t be sold, ensuring that this process is done responsibly and in an environmentally friendly manner.

Aligning with organizations like Shapiro that specialize in organic waste disposal and recycling, including beverage destruction, can provide breweries with the expertise to optimize their sustainability efforts. Through collaboration, breweries can create a closed-loop system that reflects their commitment to the environment while maintaining the integrity of their product.

FAQ

A keg coupler is a device that connects the gas and beer lines to your keg. It essentially acts as a key that unlocks the keg, allowing CO2 in (to pressurize the keg and push the beer out) and letting beer flow out into the lines leading to the tap. Each coupler is designed to fit a specific keg valve, ensuring a secure and sealed connection.

No, all kegs do not use the same taps. There are different types of keg couplers (taps) required for different keg styles, which correspond to the variety of valve designs used by keg manufacturers. It’s important to match the correct coupler to the keg to create a proper seal and dispense the beer effectively.

The number of beers in a keg varies depending on the size of the keg and the size of the serving. Here’s a quick breakdown using U.S. standard 16oz pints 12oz servings:

| Keg Size | Volume (gallons) | Pints (16 oz) | 12 oz Beers |

| Full Keg (Half-Barrel) | 15.5 | 124 | 165 |

| Pony Keg (Quarter-Barrel) | 7.75 | 62 | 82 |

| Sixth Barrel (Sixtel) | 5.16 | 41 | 55 |

| Cornelius Keg (Corny) | 5.0 | 40 | 53 |

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.