From the dawn of civilization, agriculture has been the backbone of human evolution. As civilizations grew, the pressures on agriculture increased, necessitating the discovery of newer techniques to optimize outputs. While approaches like acclimatization, mutation breeding, and genetic engineering have been groundbreaking, recent attention has been steered towards biosolids.

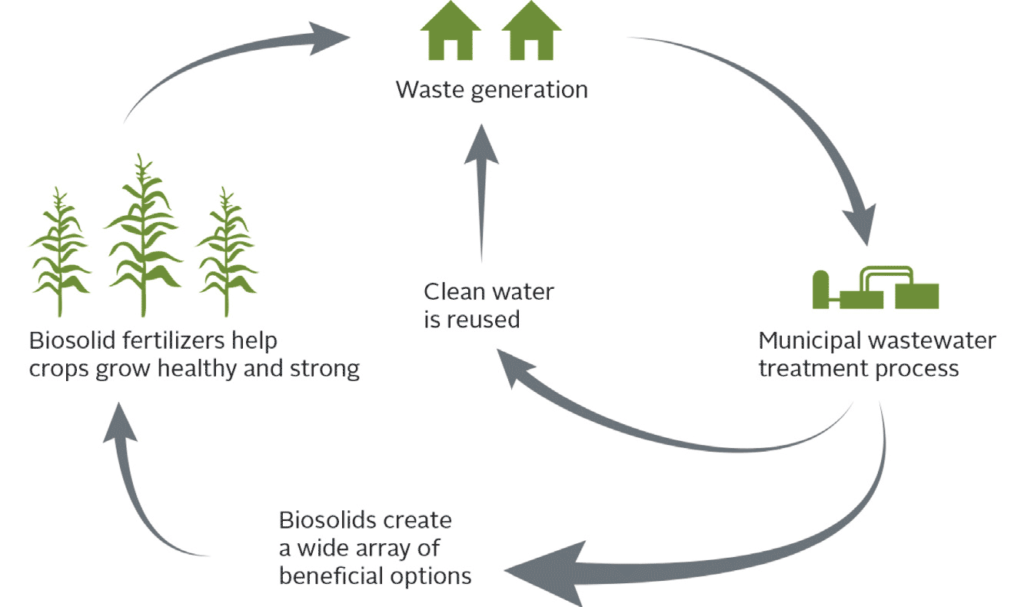

A byproduct of wastewater treatment, biosolids promise to not only enhance agriculture but also pivot the perspective on waste, particularly liquid waste. Here’s a comprehensive look at the intriguing world of biosolids.

Key Takeaways

- What are Biosolids: Biosolids are nutrient-rich organic materials resulting from the treatment of domestic sewage, offering an alternative to chemical fertilizers and playing a crucial role in sustainable agriculture.

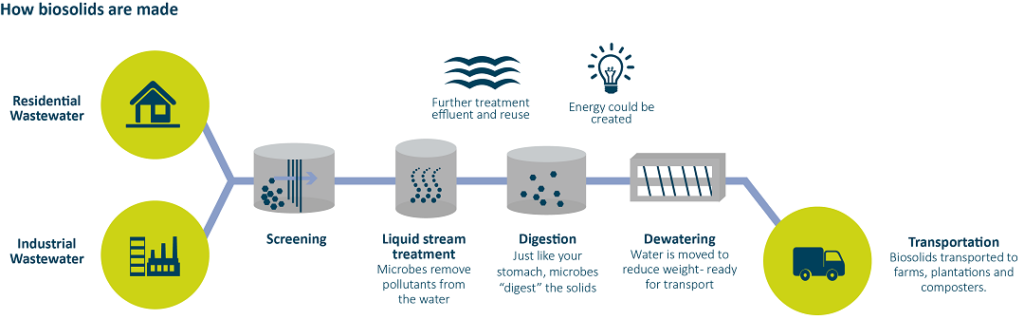

- Production Process: The transformation from sewage to biosolids is a multi-stage process involving initial collection, primary and secondary treatment, sludge digestion, dewatering, final treatment, and quality assurance.

- Types of Biosolids: There are primarily two classes of biosolids, Class A and Class B, each having undergone different treatments and thus differing in their application and safety standards.

- Applications and Benefits: Beyond their agricultural application as a sustainable fertilizer, biosolids play a role in land reclamation and energy production. They reflect a functioning circular economy and provide both environmental and economic benefits.

- Concerns and Expertise Requirement: While biosolids bring many advantages, there are concerns related to residual chemicals, odors, and regulatory challenges. Proper management, expertise, and understanding of these byproducts are essential to leverage their benefits without unintended consequences.

What are biosolids?

Biosolids are nutrient-rich organic materials produced from the treatment of domestic sewage within a wastewater treatment facility. When sewage is treated, it splits into two components: treated water and biosolids.

These biosolids contain valuable nutrients like nitrogen, phosphorus, and potassium, making them an effective and sustainable alternative to chemical fertilizers when applied to land. They can be used to improve and maintain productive soils and stimulate plant growth, making them a valuable resource for agriculture and land reclamation projects.

Classes of biosolids

It’s important to note that there are different grades or classes of biosolids, mainly Class A and Class B, which differ based on their pathogen content and the treatment they’ve undergone.

Class A

Class A biosolids undergo intensive treatment, removing all detectable levels of pathogens, creating a product safe for unrestricted land application. This classification allows the biosolids to be used freely in agricultural lands, contributing to soil health and crop nutrition.

Class B

Class B biosolids, while still rich in nutrients, contain a reduced pathogen level, necessitating certain restrictions in their application to protect public health and the environment. They are mostly used in restricted environments where potential exposure to humans can be controlled.

How are biosolids made?

From sewage to biosolids, the transformation is a marvel of modern engineering.

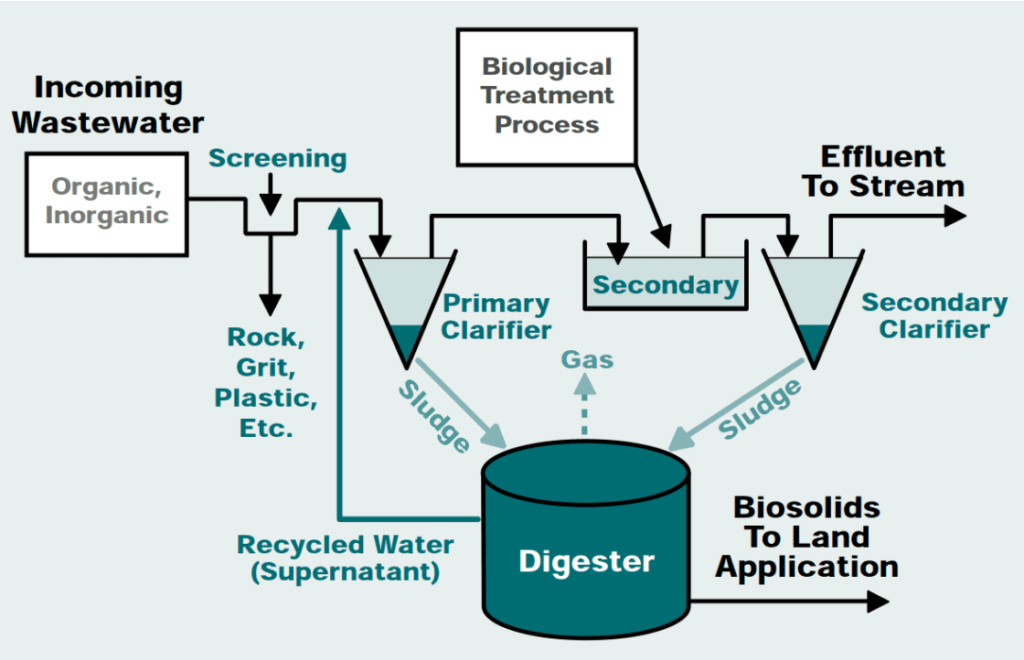

Initial Collection and Screening

The first step in the biosolids wastewater treatment journey begins with the collection of wastewater from various sources, such as homes, industries, and storm drains. This wastewater is channeled into a central treatment facility, where the primary goal is to screen and remove large, non-biodegradable materials such as plastics, grit, and other foreign objects that might have found their way into the sewage system.

Primary Treatment

Following the screening process, the wastewater undergoes primary treatment. This stage aims to separate solids from the liquid portion through sedimentation. Here, gravity plays a critical role as heavy solids settle at the bottom of the settling tanks, forming a sludge, while lighter materials, like oils and greases, float to the top and are skimmed off. This process helps in reducing the total solid content and preparing the sludge for further treatment.

Secondary Treatment

Entering the secondary treatment phase, the focus shifts to the removal of organic materials and nutrients present in the liquid portion. This is achieved through biological processes where microorganisms feed on the organic substances. Aerobic bacteria, thriving in oxygen-rich environments, play a vital role in breaking down organic compounds, thereby reducing the biological oxygen demand (BOD) of the wastewater.

Sludge Digestion

The sludge collected from the primary and secondary treatment stages undergoes further treatment to stabilize and sanitize the material. The digestion process, either aerobic or anaerobic, involves the use of microorganisms to decompose organic matter in the sludge wastewater. This process not only reduces the volume of the sludge but also generates biogas, a renewable energy source, thus exhibiting the potential of biosolids wastewater treatment in energy recovery.

Dewatering

After the digestion process, the sludge has transformed into biosolids, but it still contains a high water content. Dewatering is the process that reduces the water content considerably, making the biosolids easier and more cost-effective to transport. This stage employs various mechanisms such as centrifuges, filter presses, or drying beds to remove a significant amount of moisture from the biosolids.

Final Treatment and Preparation

Before biosolids can be put to beneficial use, they undergo a final treatment where they are further processed to eliminate pathogens and other harmful components. Depending on the intended use, biosolids may be subjected to advanced treatments like composting, lime stabilization, or heat drying to achieve Class A or Class B biosolid standards. This ensures that the final product is safe, nutrient-rich, and ready for application in agriculture or other fields.

Quality Assurance and Distribution

Quality assurance is a critical aspect of the biosolids wastewater treatment process. Before distribution, biosolids undergo rigorous testing to ensure they meet the necessary safety and quality standards set by regulatory agencies. Once cleared, these nutrient-rich biosolids are ready to be distributed and utilized in various applications.

Biosolids technology

Understanding biosolids technology requires recognizing the intricate machinery and systems at work. At the heart of this are advanced centrifuges and digesters.

Machinery Mechanisms

- Anaerobic Digesters: Serving as the heart of biosolids production, these are essentially large tanks where bacteria break down organic materials in the absence of oxygen. These digesters facilitate the transformation of wastewater solids into stabilized biosolids.

- Centrifuges and Belt Presses: Integral in the dewatering process, these machines effectively remove water from the semi-solid sludge, optimizing the consistency of biosolids for land application.

- Thermal Dryers: Employed in advanced treatment facilities, thermal dryers remove moisture, resulting in a dry, pelletized product that’s easy to transport and apply.

Advancements in Processing

- Alkaline Stabilization: A process where lime is added to biosolids, increasing their pH and subsequently eliminating pathogens. This results in a product safe for land application without the pathogen-related restrictions seen with Class B biosolids.

- Composting: An aerobic process where biosolids are combined with a bulking agent like wood chips. The combined material is then piled and turned periodically to introduce air, resulting in a humus-like end product that can be safely applied to lands.

- Thermal Hydrolysis: An innovative pretreatment method where the sludge is subjected to high temperatures and pressures before undergoing anaerobic digestion. This not only improves the digestion process but also enhances biogas yield, presenting energy generation possibilities.

Monitoring and Control Systems

Advanced biosolid production facilities rely heavily on computerized monitoring systems. These systems track key parameters such as temperature, pH, and moisture content, ensuring that the processes remain within specified limits.

What are biosolids used for?

Agricultural Application

A significant portion of biosolids finds its way into agricultural lands as a potent fertilizer alternative, enhancing soil structure, nutrient content, and water retention capacity. This leads to improved crop yields and decreased reliance on synthetic fertilizers.

Land Reclamation

Biosolids have proven their mettle in land reclamation projects, revitalizing lands stripped of nutrients due to intensive agriculture or mining activities. The rich organic content of biosolids helps initiate a new cycle of ecological succession, fostering biodiversity and soil health.

Energy Production

In some pioneering setups, biosolids have been used as a renewable energy source. Through anaerobic digestion, biosolids can generate biogas, a renewable energy form, thus contributing to a sustainable energy future.

Benefits and advantages

Environmental Impact

In the larger scheme of things, biosolids serve as a testament to a functioning circular economy. By recycling nutrients and organic matter back into the soil, biosolids reduce the dependence on chemical fertilizers, mitigating their environmental impact.

Economic Benefits

For farmers and wastewater treatment facilities alike, biosolids offer tangible economic benefits. Farmers can substantially reduce fertilizer costs, while treatment facilities can generate revenue streams by selling biosolids, a significant shift from the erstwhile expense-heavy disposal procedures.

Risks and disadvantages

Chemical Concerns

The primary risks lie in the residuals. Despite comprehensive treatment processes, biosolids can still carry minute traces of heavy metals, pharmaceuticals, and other synthetic chemicals. Over time, these contaminants might accumulate and pollute the soil. This raises apprehensions about the long-term viability of the land for agriculture and the potential for these chemicals to enter the food chain. If unchecked, these contaminants can affect crop quality and potentially pose health risks to consumers.

Odor Issues

Biosolids can often emit unpleasant odors, which can be a cause of concern, especially if applied near residential areas. This can lead to conflicts with communities living nearby, which can have implications not just for the immediate application but also for the broader acceptance of biosolids as a sustainable solution.

Regulatory Challenges

The regulatory landscape surrounding biosolids is intricate and ever shifting. Complying with local, state, and federal regulations can be demanding. A failure to comply can result not just in financial penalties but can also put a dent in the reputation of the involved entities. Furthermore, the inconsistency in regulations across regions can pose challenges for those looking to apply biosolids on a larger scale or across different jurisdictions.

Let us help you transform your waste into energy

The incorporation of biosolids into agriculture is a testament to human ingenuity. It not only addresses waste management concerns but also promotes sustainable agricultural practices. However, managing wastewater byproducts requires expertise and a robust legal understanding. Mishandling can have far-reaching implications for the environment, health, and even the economy.

That’s where we at Shapiro With a vast national reach, we are more than just a agricultural and farm waste management company. We are a partner committed to guiding you every step of the way.

Our collaborations with some of the industry’s front-runners, those who employ the latest waste management techniques, ensures that you are getting the best, most up-to-date advice and solutions. Together, we can help you navigate the intricacies of wastewater byproduct management, ensuring that you’re not only compliant with all regulations but also paving the way for a more sustainable future.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.