As we grapple with challenges like plastic pollution and waste disposal, bioplastics offer an innovative solution. Not only do they serve as an alternative to conventional plastics, but they also give us a fresh perspective on what we’ve long considered ‘waste.’ By using dairy byproducts to produce bioplastics, we open new avenues for recycling and environmental conservation. This dual benefit—lessening our reliance on harmful plastics and finding useful applications for waste—makes the subject well worth our attention.

Key Takeaways

- Dairy waste, primarily whey, can be converted into usable bioplastics, offering a dual benefit of waste management and plastic reduction.

- Bioplastics from dairy waste, like Polylactic Acid (PLA) and Polyhydroxybutyrate (PHB) serve as alternatives to traditional plastics and find applications in areas ranging from packaging to medical supplies.

- Initial separation and purification processes are crucial steps for deriving high-quality bioplastics from dairy waste.

- While promising, dairy waste bioplastics face challenges such as limited production capacity, potential inferiorities in material properties, and purification complexities.

- Despite these challenges, the potential for reducing environmental impact and providing sustainable solutions makes dairy waste bioplastics a topic worth investigating further.

The Environmental Issue with Traditional Plastics

It’s hard to ignore the numbers when they’re as staggering as this: according to Statista, nearly 400 million metric tons of plastic were produced globally in 2021. When you grasp the scale of that production, the issue of plastic waste starts to look overwhelming. One of the crucial issues is the longevity of plastic. While its durability makes it useful for many applications, that same trait ensures that it remains in our environment for years, often outliving its initial purpose by several lifetimes.

Not all plastics are recyclable. Contrary to popular belief, a substantial percentage never makes it to recycling facilities and ends up either in landfills or incinerated. Studies show that only 9% of all plastic produced in a year gets recycled, with 19% being incinerated and a troubling 50% accumulating in landfills. The remaining 22% end up in the natural environment or uncontrolled dumpsites.

These unrecycled plastics often break down into smaller particles known as microplastics. These minute particles have the ability to enter water systems, and once there, they pose a great threat to aquatic life, who often mistake them for food. This implication extends to us as well, as there’s growing evidence that these microplastics can enter the human food chain through fish and other aquatic animals we consume.

The Rise of Bioplastics

Bioplastics, once an experimental material relegated to academic labs, began to command greater attention in the early 2000s. Ecological consciousness intersected with scientific breakthroughs, propelling them into a wider sphere of influence. They promised to lower carbon emissions. Even more enticing was their ability to break down naturally and their reduced dependence on fossil fuels.

While they have indeed gained traction and momentum over the years, it’s important to acknowledge that they aren’t without their challenges. Current primary sources like corn and sugarcane have some limitations. These crops are also used for food production, creating competition for resources like land and water. Additionally, not all bioplastics are as sustainable as they may seem at first glance; some require energy-intensive processes for their production or fail to decompose as readily as hoped.

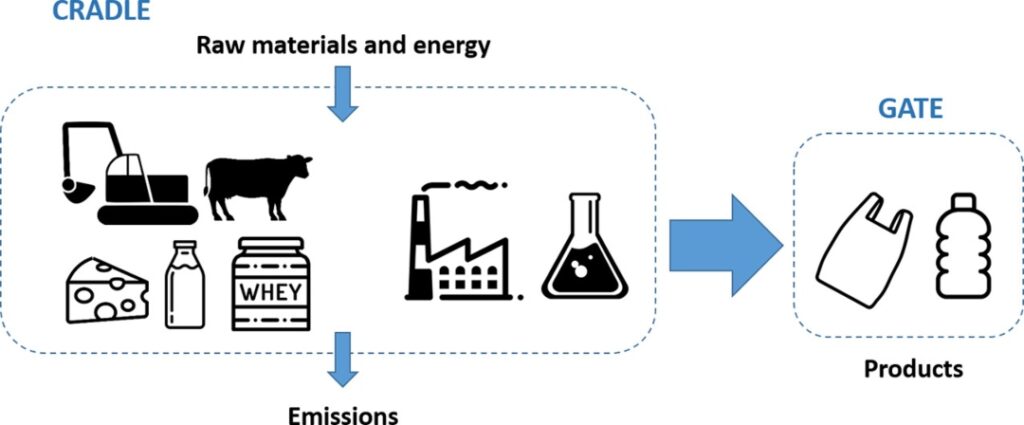

Converting Dairy Waste to Bioplastics

Dairy Waste: An Overview

Each year, an overwhelming 180-190 million tons of whey from cheese are produced as a byproduct of the global dairy industry. It’s a figure that presents not only operational challenges but also serious environmental concerns. Whey waste can significantly lower the levels of dissolved oxygen in aquatic systems, thereby impacting marine life detrimentally.

Additionally, existing methods for dairy waste management fall short of resolving the issue in its entirety. Although some waste finds utility in animal feed or anaerobic digestion, a substantial amount remains untreated. This contributes to soil degradation and releases harmful greenhouse gases such as methane.

In the grand scheme of things, dairy waste is an environmental challenge that needs immediate attention. The scale at which whey and other dairy byproducts are generated poses the question: can we do better than merely manage the waste? Given its environmental footprint, it becomes evident that innovative, sustainable solutions must be sought out.

The Science Behind the Conversion of Dairy Waste to Bioplastics

Understanding Dairy Waste Composition

Dairy waste primarily consists of organic components such as lactose, proteins, and fats. Whey, a significant byproduct, is especially intriguing for its bioplastic potential. Predominantly made up of water, whey also features valuable constituents like lactose, minerals, and proteins.

Whey’s rich lactose content makes it a suitable feedstock for microbial fermentation processes essential in bioplastic production. Additionally, the proteins found in whey contribute to the mechanical properties of bioplastics, making them more durable and versatile.

Types of Bioplastics from Dairy Waste

Polylactic Acid (PLA)

Polylactic Acid, or PLA, comes from the fermentation of lactic acid, which is derived from whey. Unlike traditional plastics, which are produced from petroleum, PLA taps into the immense volume of dairy byproducts that would otherwise contribute to environmental degradation. It holds promise for applications in packaging, disposable cutlery, and even in the medical field for sutures and implants. While it isn’t a fix-all solution—PLA does have limitations in strength and temperature resilience—it stands as a noteworthy alternative to petroleum-based plastics.

Polyhydroxybutyrate (PHB)

Polyhydroxybutyrate (PHB), another intriguing development, also originates from dairy waste. It’s obtained through bacterial fermentation processes. PHB is fully biodegradable and even water-resistant. Applications range from agricultural films to controlled-release medicine capsules. A significant advantage of PHB is its higher resilience compared to PLA, particularly in the context of mechanical strength and resistance to higher temperatures.

Microbial Fermentation Processes, Refinement and Processing

Initial Separation: Centrifugation or Filtration

After fermentation has taken place to produce the appropriate biopolymer, (PLA or PHB), the next hurdle is to separate and purify it from a complex mixture of cells, unutilized nutrients, and other metabolic byproducts. Initially, the fermentation broth undergoes centrifugation or filtration to remove larger particulates, primarily bacterial cells.

Solvent Extraction for Concentration

The extracted biopolymer then often undergoes a solvent extraction process. This involves dissolving the biopolymer in an organic solvent that is immiscible with water, thus allowing for easier separation. Following this, the solvent is evaporated, leaving behind a more concentrated form of the biopolymer.

Advanced Purification and Drying

For the highest grade of bioplastic, additional purification steps are employed. These may include techniques such as crystallization, which further isolates the biopolymer from any remaining contaminants. As a last step, the purified biopolymer is typically subjected to a drying process to remove any residual moisture, thereby ensuring it meets the standards required for commercial applications.

Dairy Waste Bioplastics vs Other Bioplastics

One major advantage of using dairy waste as a source is its ability to repurpose a byproduct that would otherwise contribute to environmental degradation. Plastics made from milk protein also often require less energy to produce compared to their fossil fuel-based counterparts.

Pros:

- Resourceful utilization of dairy byproducts

- Typically requires less energy to produce

- Generally biodegradable

Cons:

- May require advanced purification processes

- Limited range of material properties

- Potential competition with food-grade whey applications

Starch-Based Bioplastics

Starch-based bioplastics are commonly produced from corn, potatoes, or tapioca. They are often used in edible packaging, disposable cutlery, and compost bags.

Pros:

- Abundant and renewable feedstock

- High biodegradability

- Lower cost of raw materials

Cons:

- Usually less durable than conventional plastics

- Can compete with food sources

- Often requires blending with other polymers for increased functionality

Cellulose-Based Bioplastics

Derived from wood fibers, these are generally not used for items that need to be strong or moisture resistant. They are most frequently used in film and sheet applications.

Pros:

- Non-food-based feedstock

- High tensile strength

- Biodegradable

Cons:

- Limited moisture resistance

- Energy-intensive production

- Expensive purification processes

Comparison with Dairy Waste Bioplastics

Compared to starch-based and cellulose-based bioplastics, those derived from dairy waste offer a unique advantage: they give a second life to what would otherwise be waste. While starch and cellulose come from dedicated crops or trees, dairy waste is a byproduct that provides an added environmental advantage by recycling waste streams. However, dairy-based bioplastics face challenges such as needing more advanced purification steps and having a narrower range of material properties.

Potential Applications of Dairy Waste Bioplastics

The value of bioplastics made from dairy waste extends far beyond simply being an eco-friendly alternative to traditional plastics. Their diverse range of applications holds the promise for more sustainable practices across various sectors.

Food Packaging

Bioplastics from milk and cheese waste excel in applications where biodegradability is a key factor. Food packaging, such as wrappers, trays, and containers, are excellent candidates. These helps mitigate the environmental impact by decomposing more readily than traditional plastics.

Agricultural Tools

Biodegradable planters, mulch films, and seedling containers are increasingly being made from dairy waste bioplastics. Such agricultural tools assist farmers while reducing the environmental footprint of farming practices.

Medical Supplies

The biocompatible nature of these bioplastics, like PLA, makes them suitable for medical applications such as sutures, implants, and drug delivery systems. They can safely break down in the body, negating the need for secondary removal surgery.

3D Printing Material

They can also be used as filament in 3D printers. They offer a renewable alternative to conventional 3D printing materials, reducing the overall environmental impact of rapid prototyping and custom manufacturing.

Textiles

PLA fibers derived from dairy waste can be woven into textiles for apparel, upholstery, and other fabric-based products. These textiles are often breathable, hypoallergenic, and—most importantly—biodegradable.

Limitations and Challenges of Dairy Bioplastics

While dairy waste bioplastics show considerable promise, there are challenges to acknowledge.

Limited Production Capacity

Production capacity is one such hurdle; scaling from lab tests to industrial levels is often complicated and costly. This might result in limited availability initially as the industry grows to meet demand.

Material Properties

Material properties can also pose concerns. Depending on the application, they might exhibit reduced tensile strength or thermal resistance compared to traditional plastics. Thus, they may not be suitable for every single use case.

Purification Hurdles

Another issue revolves around the purification of dairy waste. Removing contaminants from the initial waste product to produce a high-quality bioplastic involves a meticulous process. Though some might question whether this can be achieved consistently and at scale without risking contamination.

Conclusion

Despite these challenges, the world of dairy-derived bioplastics still shows enormous promise and potential. These hurdles are not insurmountable but rather technological puzzles, awaiting creative solutions. As research and practice advance, the benefits could well outweigh the limitations, leading us toward a more sustainable future.

Are you in search of an innovative and sustainable solution to your dairy or agricultural waste problem? Contact Shapiro to transform your challenges into opportunities for positive environmental impact.

Dairy Waste Bioplastics FAQ

The durability of plastic made from milk varies depending on its formulation and environment. It generally decomposes faster than conventional plastics, often breaking down in a few months to a couple of years.

Casein plastic is a type of biodegradable plastic synthesized from the protein casein found in milk. It’s been used for various applications, such as making buttons, beads, and other small items.

Yes, milk can be converted into bioplastic. Specifically, the casein protein from milk is used to create casein plastic, offering an eco-friendly alternative to traditional plastics.

Plastic made from milk protein has the advantage of being biodegradable, which can reduce its environmental impact. However, it’s generally not as strong or durable as traditional plastics and is better suited for specific, short-term uses rather than general-purpose applications.

The durability of casein plastic from milk is less than that of conventional plastics. It’s generally better for items that don’t require long-term structural integrity.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.