Separating organic material from non-organic packaging is a key part of reducing waste.

And while food waste depackaging may seem simple for households and small-scale operations, it’s a completely different process at industrial levels, requiring proper technology and protocols to ensure success.

Whether you’re a food and beverage manufacturer, supply chain leader, or ESG officer, turning waste into a value-generating output offers more than economic advantages—it’s also an environmental responsibility.

Keep reading to explore the benefits of food waste depackaging for manufacturers, how the process works, and more.

Key Takeaways

- Depackaging is essential for manufacturers because packaged waste cannot go directly to composting or anaerobic digestion without proper separation.

- Landfilled food waste drives major environmental impacts, including high methane emissions, making depackaging a critical step in reducing climate impact and supporting ESG goals.

- Manufacturing waste streams are more complex than those in restaurants or households, requiring advanced systems to handle packaging, recalls, off-spec loads, and high volumes.

- Manufacturers can choose on-site or partner-based depackaging, but most benefit from third-party partners who offer lower upfront costs, reliable logistics, and compliance-ready documentation.

Why Manufacturers Need Food Waste Depackaging?

With manufacturers producing large batches of fully packaged finished goods, food waste depackaging for manufacturers is crucial to ensure proper separation, recycling, and disposal.

This need becomes even more urgent considering that an estimated 58% of the fugitive methane emissions from municipal solid waste landfills come from landfilled food waste—a major contributor to climate change.

While the food waste management hierarchy positions prevention as the most beneficial solution, other pathways like upcycling, composting, and anaerobic digestion play important roles in reducing environmental impact. In fact, one study found that composting organic waste instead of landfilling it can reduce carbon dioxide–equivalent greenhouse gas emissions by more than 50%.

All things considered, companies that generate large volumes of waste have a responsibility to manage it sustainably and reduce its environmental impact.

The Packaged Waste Challenge in Manufacturing

Managing food waste in manufacturing is very different from handling it in other settings.

Take a restaurant, for example. While restaurants have their own set of challenges, most of their waste comes from issues like overproduction, plate waste, and mishandling, among others. To recycle this waste, restaurants can simply place it in a separate bin, where it can be collected and recycled.

For manufacturers, the process isn’t as simple. Since many of the products are packaged, they must have an advanced depackaging system before the organic waste can be recycled. In fact, without depackaging, these loads are typically rejected by AD facilities and composters, making it a required step for greater sustainability.

So why do manufacturers produce so much waste?

Common causes of waste include:

- Off-spec batches

- QA/QC rejects

- Labeling errors

- Allergen misprints

- Damaged packaging

- Short production cycles

- Recalls

That said, companies must have an efficient system for separating waste from packaging to reduce environmental impact and ensure compliance with food waste laws.

Why Packaged Goods Can’t Go Directly to Composting or AD

Composters and digesters require a clean, low-contamination organic stream. However, packaging materials like plastics, cans, cartons, pouches, and multilayer films prevent this, making organic waste depackaging essential.

Depackaging systems separate the organics from their packaging, producing a clean feedstock for composting or anaerobic digestion while diverting the remaining materials for recycling or more efficient disposal.

While advancements such as sustainable beverage packaging may help reduce contamination in the future, the point still stands: packaged waste must be properly separated before it can enter any responsible recovery pathway.

Environmental Impact & Regulatory Drivers

Advanced food waste solutions for manufacturers, such as composting and anaerobic digestion, offer a range of environmental benefits, including:

- Reduced greenhouse gas emissions: Food loss and waste account for 8-10% of annual global greenhouse gas emissions. By diverting food waste from landfills, companies can significantly reduce their environmental impact and help mitigate the climate crisis.

- Conservation of natural resources: Producing food requires labor, energy, water, and land—all of which are wasted when food is discarded. Companies that fight food waste with a circular economy maximize the value of these resources and reduce unnecessary strain on natural systems.

- Creates valuable new resources: Food waste can be upcycled into beneficial products. Compost, for example, can enhance soil health and support sustainable farming, while biogas from anaerobic digestion serves as a renewable energy source.

Food waste depackaging supports all of these environmental outcomes by efficiently removing packaging so organic material can be accepted by composting and anaerobic digestion facilities—enhancing recovery, reducing contamination, and improving overall sustainability.

How Food Waste Depackaging Works

Here are the key details you need to know about how the process works:

1. From Packaged Products to Clean Organics

Food depackaging equipment opens, separates, and screens packaged goods to produce a high-purity organic stream suitable for anaerobic digestion or composting. In addition, this separation creates a packaging stream that is drained, dewatered, and sent for recycling or proper disposal. The goal?

To ensure organic material is contamination-free and acceptable to recovery facilities while managing packaging responsibly.

2. What Happens to the Separated Packaging

The outcome of the separated packaging depends on the materials involved. Plastics can often be recycled to support a more sustainable economy, while fiber-based packaging may be composted where allowed.

Regardless of the method, it’s essential that packaging is managed responsibly, as packaged food waste recycling helps reduce microplastic generation and improves overall recycling outcomes.

3. Partner-Based Depackaging Services (Why Most Manufacturers Choose This Option)

Pre-consumer food waste management is a complex task. Not only does it require advanced depackaging systems for greater efficiency, but it also demands transportation logistics and proper handling to ensure compliance. Companies must also understand how to recycle their waste effectively, choosing between pathways such as anaerobic digestion and composting.

By partnering with a waste-management specialist, manufacturers can reduce the headache of navigating this entire process on their own.

At Shapiro, we help manufacturers streamline expired and off-spec product destruction. With a national network of organics processing outlets, we provide certificates of destruction, audit-ready documentation, and reliable feedstock management for anaerobic digestion.

From supporting large-scale manufacturers to helping companies address food waste on farms, we ensure materials are handled responsibly and efficiently. Contact us to learn more about our solutions.

Depackaging Options: On-Site vs. Partner-Based Depackaging

So how do on-site and partner-based depackaging solutions compare?

Let’s take a look:

1. On-Site Depackaging Systems

On-site depackaging is the separation of organic material from non-organic packaging at the location where the waste is generated.

By managing waste at the source, companies can reduce transportation needs and improve operational efficiency. For high-volume waste generators, on-site depackaging provides an efficient and sustainable solution that strengthens waste-reduction initiatives and ESG performance.

However, investing in food depackaging equipment comes with high upfront costs and the need for trained personnel. While this approach is beneficial for some large-scale operations, it does require significant capital investment and specialized training to implement effectively.

2. Partner-Based Depackaging (Most Common for Manufacturers)

As mentioned above, partner-based depackaging is a common choice for manufacturers. Why?

It offers faster implementation, established logistics, a predictable cost structure, and greater reliability during recalls, product withdrawals, or seasonal volume surges. Third-party partners also bring specialized expertise, existing infrastructure, and compliance-ready documentation—advantages that can be difficult and costly to build in-house.

Overall, partnering with a third-party depackaging company makes it far easier to implement food waste solutions for manufacturers, making it an efficient and practical option for many organizations.

Comparison Table: On-Site vs. Partner-Based

| Category | On-Site Depackaging | Partner-Based Depackaging |

|---|---|---|

| Definition | Separation done at the facility where waste is generated | Waste sent to a third-party for depackaging |

| Key Benefits | Reduces transport, boosts efficiency, supports ESG goals | Fast setup, established logistics, predictable costs, high reliability |

| Ideal For | Large operations with consistent waste volumes and the necessary infrastructure | Most manufacturers seeking a simple, low-risk solution |

| Costs | High upfront investment and trained staff required | Lower upfront cost with stable pricing |

| Complexity | Higher; equipment, maintenance, and compliance handled internally | Lower; provider manages processing, logistics, and compliance |

| Scalability | Limited by on-site capacity and expertise | Highly scalable through provider networks |

3 Business Benefits of Depackaging

Keep reading to discover the operational, financial, and environmental benefits of food waste depackaging.

1. Operational Benefits

There are several operational benefits of food waste depackaging for manufacturers. Companies with an efficient depackaging system experience reduced manual handling, faster recall response, cleaner material streams, and fewer rejected loads, resulting in greater overall operational efficiency.

2. Financial Benefits

By supporting food waste upcycling, organic waste depackaging helps companies lower landfill disposal and hauling costs and reduce potential fees for noncompliance with food waste laws. Even more, companies that implement solutions like composting and the anaerobic digestion of food waste can create new revenue streams to increase their bottom line.

3. Environmental & Compliance Benefits

Food waste depackaging and recycling increases landfill diversion, reduces methane emissions, and maximizes resource efficiency. In addition to benefiting the environment, this helps companies meet ESG and CSR goals and align with state organic waste bans and corporate sustainability commitments.

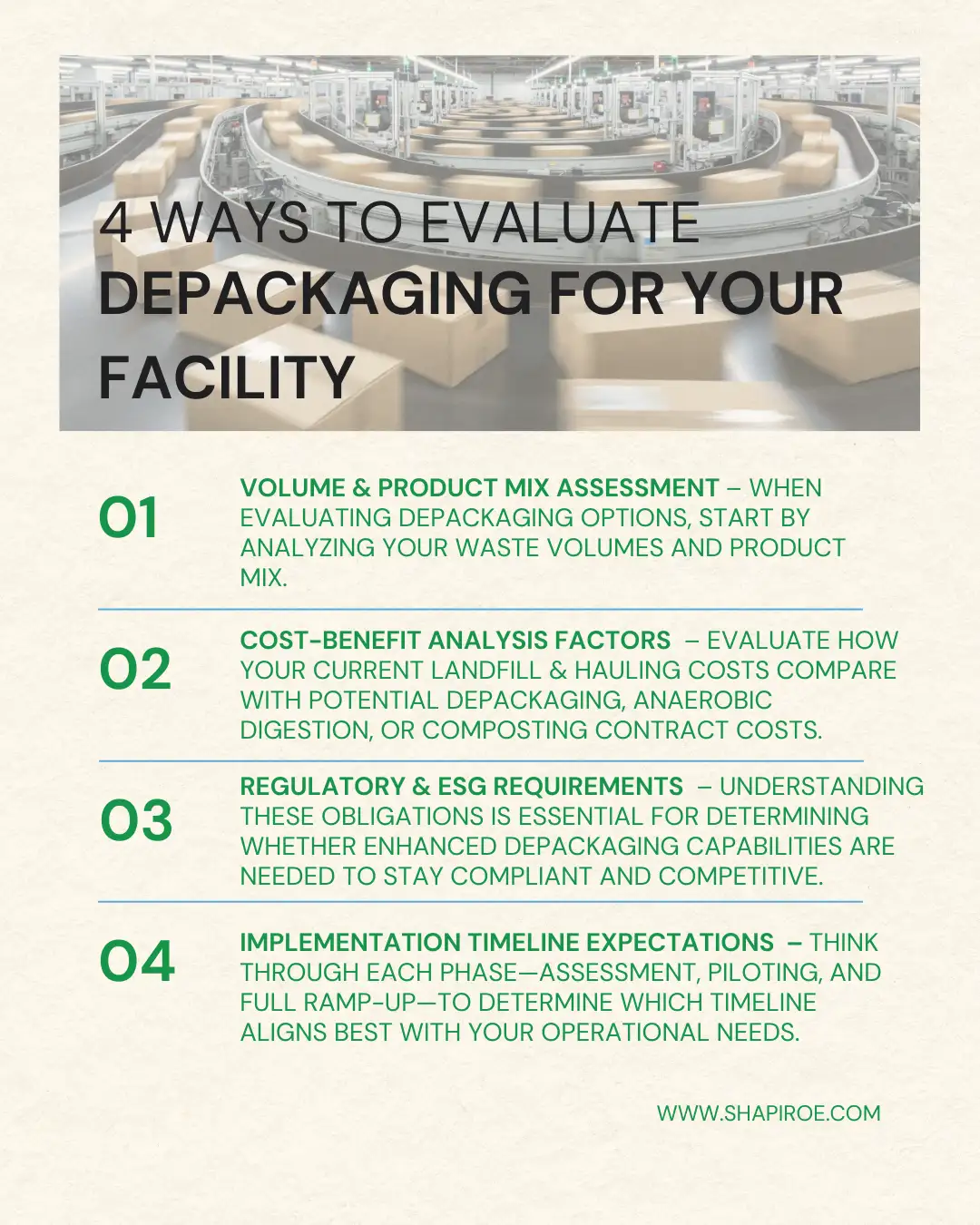

How to Evaluate Depackaging for Your Facility

If you’re evaluating your options for creating a depackaging strategy, here’s what you should consider:

1. Volume & Product Mix Assessment

When evaluating depackaging options, start by analyzing your waste volumes and product mix. Ask key questions such as:

- How many tons per month are generated?

- Are volumes steady, or do they spike seasonally?

- What packaging formats are involved?

- Do you handle branded, off-spec, or recall loads?

Understanding these factors will help determine whether on-site systems or partner-based solutions are better suited for your facility.

2. Cost-Benefit Analysis Factors

Next, evaluate how your current landfill and hauling costs compare with potential depackaging, anaerobic digestion, or composting contract costs. Consider surcharges, the risk of rejected loads, and any financial impacts associated with noncompliance or contamination.

3. Regulatory & ESG Requirements

Do you have statewide organic waste bans? Need to meet corporate ESG goals, customer expectations, or retailer requirements?

With regulations and sustainability pressures increasing across the industry, understanding these obligations is essential for determining whether enhanced depackaging capabilities are needed to stay compliant and competitive.

4. Implementation Timeline Expectations

Consider how long each option takes to get up and running. Partner-based depackaging setups are typically faster, while on-site systems require more time for equipment installation, training, and permitting.

Think through each phase—assessment, piloting, and full ramp-up—to determine which timeline aligns best with your operational needs.

What to Look for in a Depackaging Partner

Since most manufacturing companies choose to work with a third-party depackaging partner, here are the qualities to look for:

1. Technical Capabilities & Certifications

A strong depackaging partner should demonstrate the technical capacity to meet your facility’s needs. Look for high organic purity rates, the ability to handle your specific packaging formats, and robust testing procedures.

Third-party certifications can also validate their process quality, safety standards, and compliance practices.

2. Geographic Coverage & Logistics

Choose a depackaging partner with the reach and flexibility to support your operations. A reliable partner offers multi-facility and multi-state coverage, the ability to manage large one-off events such as recalls, and transportation solutions that keep material moving efficiently.

At Shapiro, we provide nationwide support and maintain a strong network of partnerships that allows us to serve our clients more effectively. Our sustainable waste solutions span everything from composting and anaerobic digestion to agricultural recycling.

3. Documentation & Compliance Support

A dependable depackaging partner should provide thorough documentation to support compliance and traceability. Look for services such as Certificates of Destruction, chain-of-custody documentation, and reporting that supports ESG tracking and audit requirements.

Depackaging in Your Zero-Waste Manufacturing Strategy

Depackaging is an essential step in any zero-waste plan. By separating packaging from organics, it enables higher-value solutions like upcycling, composting, and anaerobic digestion, helping manufacturers reduce landfill use and achieve sustainability goals.

At Shapiro, we help companies manage packaged food more sustainably. With nationwide support and proven depackaging solutions, we make it easier to build and scale a zero-waste strategy that actually works.

Contact us to get started.

FAQs about Food Waste Depackaging

Food waste depackaging for manufacturers is the process of separating organic material from its packaging so the waste can be properly recycled, upcycled, composted, or sent to anaerobic digestion.

Packaged food waste can’t go directly to AD or composting because these facilities require a clean, low-contamination organic stream, and materials like plastics, films, and cartons interfere with the process and can damage equipment, contaminate end products, and cause loads to be rejected.

Yes, depackaging systems can handle recalls and branded products by separating the packaging, destroying the contents, and providing documentation for compliance and brand protection.

Depackaging systems can process a wide range of packaging formats, including plastics, pouches, cartons, bottles, jars, cans, and multilayer films.

Companies must consider their waste volumes, infrastructure, budget, and operational needs. On-site equipment works best for large, consistent waste streams with the capacity to manage depackaging systems, while most manufacturers benefit from a partner for faster setup, lower upfront costs, and simpler logistics.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.