Industrial wastewater treatment prevents pollution, safeguards the environment, and ensures compliance with legal regulations.

And with 13 tons of hazardous waste produced every single second worldwide, or nearly 400 million tons each year, it’s clear that companies and governments must implement comprehensive strategies to minimize environmental harm.

Understanding the proper disposal of liquid waste is especially important for high-waste industries such as manufacturing, food production, and mining, where industrial wastewater treatment systems play a key role in supporting sustainability and improving efficiency.

Keep reading to explore common industrial wastewater treatment processes, compliance requirements, and more.

Key Takeaways

- There are different industrial wastewater treatment methods depending on the type of wastewater a company produces, with physical, chemical, and biological methods all playing a role in removing contaminants.

- A typical industrial wastewater treatment process includes coagulation, flocculation, sedimentation, filtration, disinfection, and distribution or discharge.

- Wastewater treatment in the food industry is essential because food production generates high-BOD, FOG-rich effluent, requiring strict regulatory compliance and biological processes such as anaerobic digestion to manage waste effectively and sustainably.

- When you partner with an experienced waste management company, they’ll evaluate your specific needs and design a treatment strategy that applies the right industrial wastewater treatment technologies to maximize sustainability.

What Is Industrial Wastewater and Why It Matters

Industrial wastewater is water containing dissolved and suspended particles released from various industrial processes, often containing contaminants such as chemicals, heavy metals, and other industrial wastes.

So why should companies care about industrial wastewater management?

Because everyone deserves access to clean, safe water, and industrial wastewater treatment helps make this possible. While it matters across all industries, it’s especially critical in industries that generate high volumes of wastewater, such as chemical manufacturing, textiles, food processing, automotive, and oil and gas.

To better understand the importance and urgency of handling industrial water contamination, look at three shocking statistics:

- 80% of the world’s wastewater flows back into the ecosystem without being treated or reused, meaning around 1.8 billion people use a source of drinking water contaminated with feces. This puts them at risk of contracting cholera, dysentery, typhoid, and polio.

- The U.S. EPA estimates that combined sewer overflows release approximately 850 billion gallons of untreated wastewater and stormwater each year.

- Industrial wastewater data from 22 countries covering 8% of the global population shows only 38% is treated and just 27% is safely treated.

All things considered, the wastewater treatment industry is essential to protecting public health and ecosystems, with regulatory bodies like the EPA guiding this change.

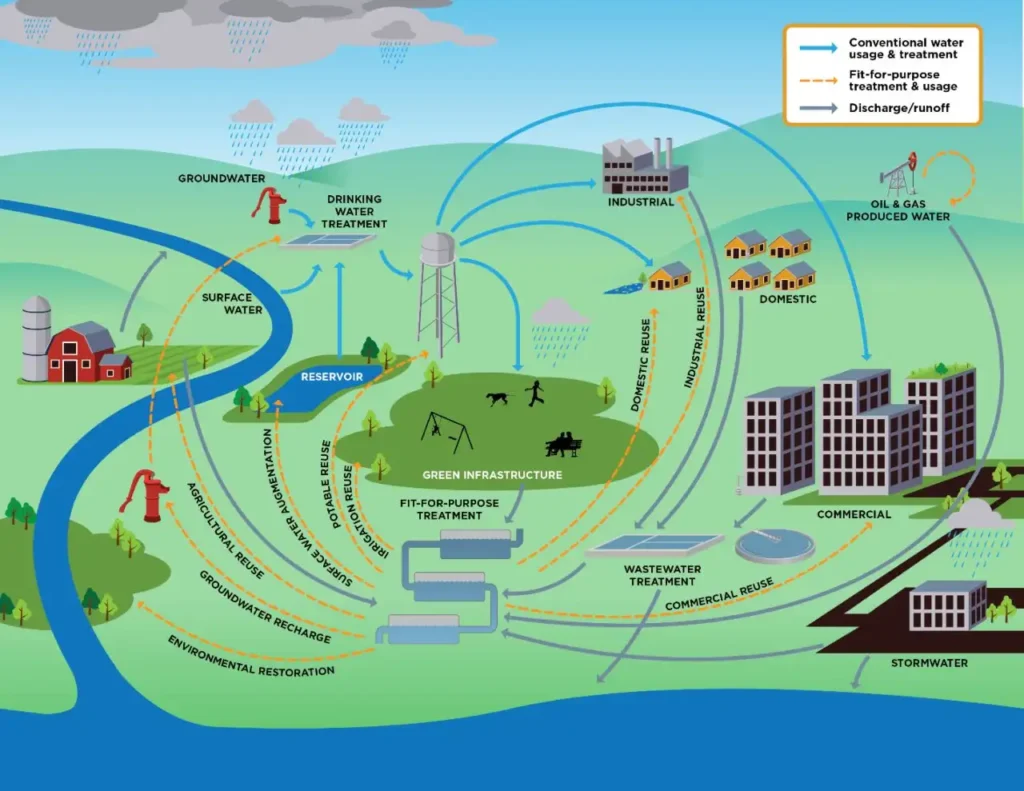

A key part of this effort is water reuse, which offers alternatives to existing water supplies and helps enhance water security, sustainability, and resilience. It involves reclaiming water from a variety of sources, treating it, and reusing it for agriculture and irrigation, potable water supplies, groundwater replenishment, industrial processes, and environmental restoration.

Common Sources of Industrial Water Contamination

Industrial activities generate wastewater streams that vary by sector, each carrying specific pollutants depending on the processes involved. Here are some of the common sources of industrial water contamination in different industries:

- Chemical manufacturing: Process effluents, equipment cleaning and washing water, and cooling tower blowdown.

- Textiles: Dye bath effluents, bleaching wastewater, and finishing rinse water.

- Food processing: Slaughterhouse effluents, dairy plant wastewater, and fruit and vegetable wash water.

- Automotive: Electroplating wastewater, paint shop effluents, and vehicle wash water.

- Oil and gas: Refinery effluents, desalter wastewater, and cooling tower blowdown.

Understanding these wastewater sources is important because they contribute to pollution, highlighting the need for effective liquid waste treatment solutions.

Pollution can generally be classified into two categories: point-source pollution and nonpoint-source pollution.

- Point-source pollution comes from a single place, making it easy to identify. Examples include pipes releasing effluent from municipal wastewater treatment plants and discharges from factories, refineries, or power plants.

- Nonpoint-source pollution comes from different places all at once, making it difficult to trace back to one source. Examples include runoff carrying fertilizers, pesticides, and manure into waterways and leaking or failing septic systems spread across neighborhoods.

These discharges often carry a mix of organic pollutants (such as fats, oils, and proteins), chemical pollutants (such as heavy metals, solvents, and pesticides), and even thermal pollutants, which occur when hot or cold water enters a natural body of water and changes its temperature.

Common Methods of Industrial Wastewater Treatment

There are different industrial wastewater treatment methods depending on the type of wastewater a company produces.

Whether you require dairy farm wastewater treatment or solutions for sectors like textiles or oil and gas, here are the common treatment methods of industrial wastewater:

1. Physical Treatment Methods

As described by ScienceDirect, “Physical wastewater treatment is defined as a series of processes that utilize physical forces to eliminate contaminants from wastewater, including screening, sedimentation, and grit removal, to separate solid particles and suspended materials before further treatment or disposal.”

As an important first stage of industrial wastewater management, physical methods such as screening capture large solids like vegetable peels, while filtration removes finer contaminants such as residual fats and oils.

2. Chemical Treatment Methods

The chemical treatment of wastewater refers to the use of chemical processes to remove, neutralize, or transform contaminants in wastewater. Methods such as coagulation, flocculation, and pH neutralization are applied when physical treatment alone cannot effectively eliminate dissolved pollutants, pathogens, or hazardous compounds, often resulting in the generation of wastewater sludge that requires proper handling and disposal.

3. Biological Treatment Methods

Biological wastewater treatment is a method that uses microorganisms, such as bacteria and nematodes, to remove biodegradable, soluble organic substances and nutrients from wastewater through natural cellular processes. The goal?

To use processes like activated sludge and anaerobic digestion to facilitate the breakdown of waste, ensuring it can be properly treated and stabilized. For instance, the biological treatment of wastewater from the food processing industry can use anaerobic digesters to convert organic matter into biogas.

Advanced Treatment Technologies

There are also additional industrial wastewater treatment technologies, such as membrane bioreactors, UV disinfection, nanotechnology, and zero-liquid discharge systems, that enhance treatment efficiency and help industries meet stricter environmental regulations.

When you partner with an experienced waste management company, they’ll evaluate your specific needs and design a treatment strategy that applies the right technologies to maximize sustainability.

6 Steps for Industrial Wastewater Treatment

Keep reading to discover the 6 key steps in a typical industrial wastewater treatment process:

1. Coagulation

Coagulation is a chemical process in wastewater treatment where coagulants are added to neutralize particle charges, causing suspended solids to clump together for easier removal. The performance of coagulation is a major factor in improving water treatment efficiency, with the most used pre-polymerized inorganic coagulants being aluminum and iron salts.

2. Flocculation

The next step is flocculation, in which gentle mixing encourages the small, destabilized particles formed during coagulation to aggregate into larger, more settleable flocs (clusters of particles). A wide range of flocculants (also known as coagulant aids) have been developed or designed to improve the flocculation process in wastewater treatment, including synthetic or natural organic flocculants and grafted flocculants.

3. Sedimentation

Sedimentation is the process where the flocs formed during coagulation and flocculation settle by gravity to the bottom of a tank, allowing clarified water to be separated from the solids. In full-scale wastewater treatment plants, primary sedimentation is used to remove particulate organic matter and produce primary sludge, which is sent to anaerobic digesters to produce biogas.

4. Filtration

Filtration is the process in which water passes through a filter to remove remaining suspended solids and flocs that were not captured during sedimentation. Using filters such as membranes, activated carbon, and sand, the goal is to improve water quality before final disinfection.

5. Disinfection

Disinfection, which involves the destruction or inactivation of disease-causing organisms, is the last step in industrial wastewater treatment. Common methods include chlorination and ultraviolet light, which ensure that water is safe for distribution and use.

Because of its importance, drinking water regulations require that treatment plants include a disinfection phase whenever surface water is the source, highlighting its critical role in protecting public health and ensuring regulatory compliance.

6. Distribution or Discharge

After the successful treatment of industrial wastewater, the water can be safely discharged into the environment or reused for specific purposes, such as potable water supplies, groundwater replenishment, and industrial processes, depending on its quality. This not only helps close the loop but also advances long-term water reuse and sustainability goals.

Regulatory Compliance in Industrial Wastewater Treatment

There are regulations in place to control water pollution from industries, including:

- The Clean Water Act (CWA): The CWA establishes the basic structure for controlling pollutant discharges into U.S. waters and regulating quality standards for surface waters. To carry this out, the EPA has implemented pollution control programs and developed national water quality criteria recommendations.

- The National Pollutant Discharge Elimination System (NPDES): The NPDES permit program, created in 1972 by the CWA, regulates point sources that discharge pollutants into U.S. waters, helping to manage wastewater discharges and protect water quality under changing conditions.

In addition to federal requirements, companies must stay up to date with state, local, and industry-specific regulations, making compliance a critical responsibility for industrial facilities. To meet these obligations, facilities are also required to obtain discharge permits and conduct routine testing to demonstrate compliance with regulatory standards.

When you partner with an experienced provider like Shapiro, you can better navigate these complex requirements and maintain confidence in your compliance strategy.

Wastewater Treatment in the Food Industry

Effective strategies for food processing industry waste and its management focus on reducing pollutants before they impact the environment, a priority reinforced by strict regulations governing effluent from food plants.

Food manufacturing, for instance, produces wastewater rich in organic matter, leading to high BOD (biochemical oxygen demand) as well as significant amounts of fats, oils, and grease from cooking and cleaning.

Left untreated, this type of wastewater can harm the environment, which is why food industry wastewater treatment plays a vital role in protecting ecosystems and ensuring regulatory compliance.

To handle this, many facilities turn to biological treatment. Aerobic systems use oxygen and bacteria to break down waste quickly, while anaerobic digestion works without oxygen and produces useful biogas in the process.

Understanding the difference between aerobic and anaerobic processes in wastewater treatment is important, as it helps food plants choose the right system to manage waste effectively.

Industrial Wastewater Compliance: Challenges and Solutions

While regulations set the framework for wastewater management, industrial facilities face real-world challenges that require both compliance awareness and practical solutions.

Common Compliance Challenges in Industrial Wastewater Management

Industrial facilities face several real-world challenges when it comes to meeting wastewater regulations:

- Evolving regulations: Federal EPA standards, state and local discharge permits, and pretreatment rules are constantly evolving, making compliance a complex and continuous task for facilities.

- High-risk sectors: Industries such as food and beverage, chemical, and manufacturing face stricter effluent standards because their wastewater contains higher levels of pollutants, making treatment more complex.

- Documentation demands: Facilities must maintain accurate records, including Certificates of Destruction and discharge monitoring reports, since errors or omissions in documentation can create serious compliance risks.

- Consequences of non-compliance: Fines, legal action, environmental harm, reputational damage, and even facility shutdowns are all possible outcomes of non-compliance.

Scalable Solutions for Industrial Wastewater Compliance

Meeting regulatory requirements doesn’t have to overwhelm industrial facilities. By using the right tools, partnerships, and systems, companies can manage compliance more effectively and adapt to changing standards.

- Independent audits and monitoring: Third-party audits and real-time monitoring systems provide transparency, help identify issues early, and simplify reporting requirements.

- Adaptable treatment systems: Facilities benefit from wastewater systems that can be tailored to specific contaminants, offering scalable liquid waste solutions that grow with operational needs.

- Regional infrastructure support: Access to regional facilities can make compliance easier by providing sustainable disposal options and stronger documentation practices. For example, on the East Coast, the Linden Renewable Energy Project helps companies manage wastewater through reliable treatment and compliance support.

- Qualified service providers: Working with experienced waste management companies like Shapiro streamlines compliance through simplified processes, reduced risk, and reliable traceability.

Conclusion

Effective industrial wastewater treatment is more than just removing contaminants—it’s about choosing the right methods, staying compliant with evolving regulations, and embracing innovative solutions.

With Shapiro’s expertise, companies gain a trusted partner to simplify compliance and achieve sustainable results.

If you’re interested in learning more about our services, contact us today to discuss our tailored waste management solutions.

FAQs about Industrial Wastewater Treatment

The three main types of industrial wastewater treatment are physical (removing solids through processes like screening), chemical (using chemical reactions to remove, neutralize, or transform contaminants), and biological (relying on microorganisms to break down organic matter).

Processes like screening and sedimentation make up the primary treatment of industrial wastewater, removing large solids, oils, grease, and other particles so the water is easier to treat in later stages.

Industrial wastewater is neutralized by balancing its pH, usually by adding lime or caustic soda to acidic water or adding acids like sulfuric acid to alkaline water.

Industrial water is treated through physical, chemical, and biological processes—such as coagulation, sedimentation, filtration, and disinfection—to remove contaminants and make it safe for discharge or reuse.

Industrial wastewater typically needs suspended solids, oils and grease, organic matter, nutrients, and other contaminants removed before it can be safely discharged or reused.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.