Upcycling, composting, anaerobic digestion—we’re all familiar with the importance of organic waste processing. However, many of us debate whether it makes more sense to build on-site infrastructure for sustainable waste solutions or rely on partner-based, off-site processing.

Whether you’re an operations director, facility manager, or high-volume waste generator, there are multiple factors to consider before making a choice, including CapEx and OpEx implications, operational readiness, compliance requirements, and more.

This article breaks down on-site vs. off-site organic waste processing to help you make a well-informed decision for your business.

Key Takeaways

- On-site systems offer full control and long-term ROI potential but require significant capital, staffing, and operational readiness, while off-site processing provides lower risk, predictable costs, and faster implementation.

- Both on-site and off-site processing can deliver key environmental and compliance benefits, such as methane reduction, landfill diversion, and stronger ESG reporting, when managed effectively.

- Off-site processing is often the more practical and cost-effective option, reducing contamination penalties, simplifying compliance, and removing the burden of equipment maintenance and permitting.

- The right choice depends on your facility’s waste volume, cost structure, regulatory obligations, implementation timeline, and internal expertise.

Why Facilities Must Decide Between On-Site and Off-Site Processing

For large waste generators, organic waste processing is unavoidable—and so is deciding whether to manage it on-site or off-site. Here’s why:

Large Generators Face Unique Waste-Profile Requirements

Large waste generators must account for factors like load variability, fluctuating contamination levels, and constantly changing regulatory requirements. Developing an effective response means creating a tailored strategy that aligns with the food waste management hierarchy and supports the facility’s operational and sustainability goals.

That said, it’s not practical to change your strategy every month; large-scale generators require a carefully planned, detailed approach that aligns with their goals, whether that’s on-site or off-site.

Compliance, Waste Bans & Rising Hauling Costs

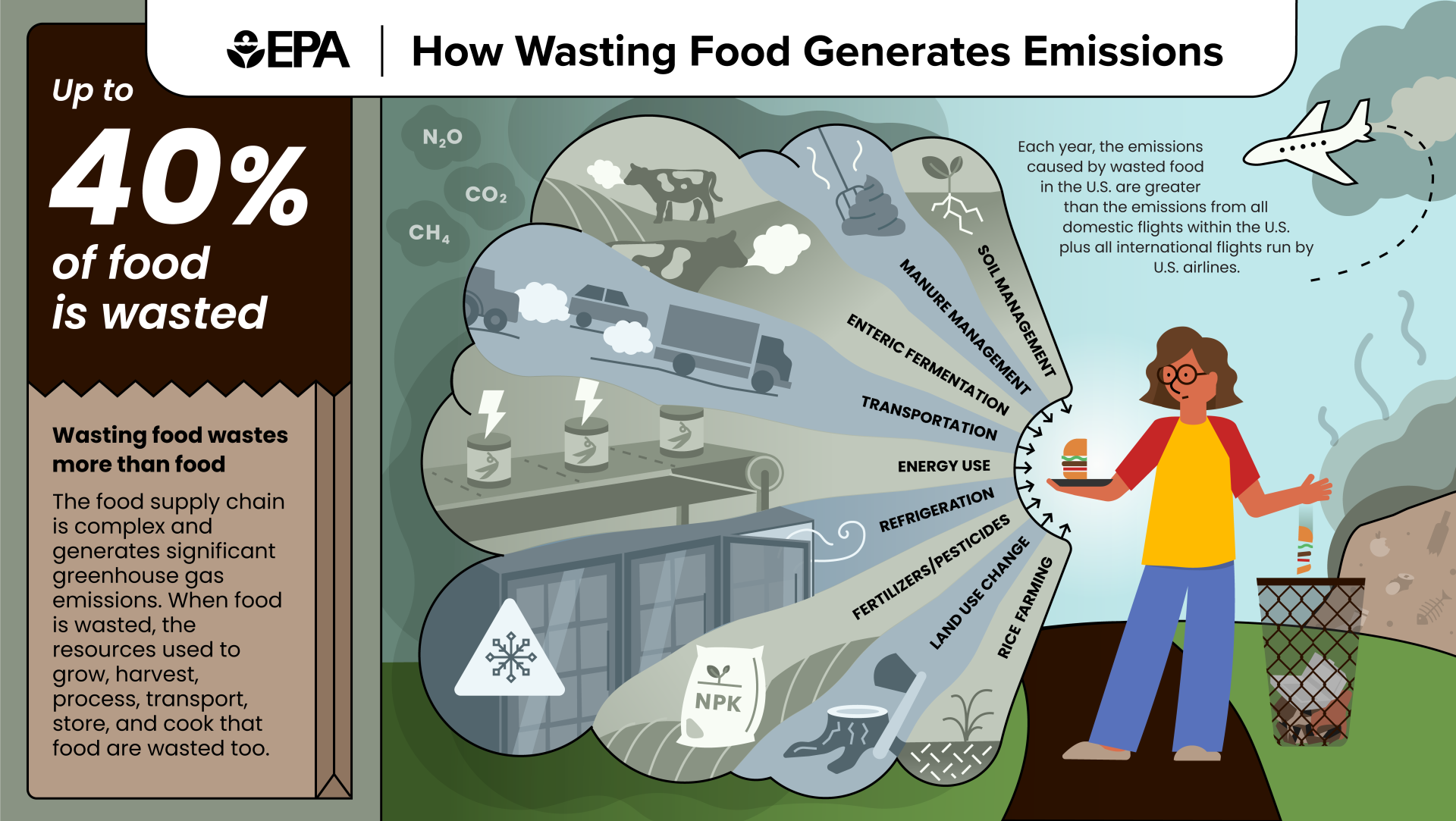

Food waste laws in the U.S. are complex, with state- and city-wide regulations that vary significantly across regions. With laws becoming increasingly strict to help the U.S. meet its goal of cutting food loss and waste in half by the year 2030, companies face growing regulatory pressure to implement a clear organic waste disposal plan.

On-Site vs. Off-Site: Comparison Overview

How does on-site infrastructure compare to off-site processing?

This table tells it all:

| Factor | On-Site Processing | Off-Site Processing |

|---|---|---|

| Cost | High CapEx; variable OpEx for equipment and maintenance | Low/no CapEx; predictable service fees |

| Risk | Higher; equipment, odors, and contamination risks managed in-house | Lower; operational risks handled by the processor |

| Control & Transparency | High; full visibility into processing quality and outputs | Lower visibility; relies on partner reporting |

| Scalability | Limited by space and equipment capacity | Highly scalable through partner facilities |

| Staffing | Requires trained staff for operation and upkeep | Minimal staffing beyond sorting and storage |

| Compliance | Generator holds most compliance responsibility | Processor carries primary compliance burden |

| Timeline | Longer to implement (permitting + installation) | Quick to launch once service is arranged |

Option 1: On-Site Organic Waste Processing

Keep reading to learn more about the requirements of on-site processing (and when it makes sense).

What On-Site Systems Actually Require

Companies that are considering setting up on-site composting or anaerobic digestion systems should be aware of the operational requirements:

- Consistent feedstock

- Stable daily tonnage

- Maintenance and staffing

- Footprint requirements

- Downtime risk

- Contamination management

- Permitting obligations

Ask yourself: Is your company equipped to manage compost processing? Do you have a stable waste feed and trained employees to support these efforts?

Why On-Site Makes Sense in Certain Scenarios

For some companies, on-site waste processing is a great option. Does it make sense for yours?

Here are the situations where on-site processing is a strong fit:

- Very large facilities with predictable loads: When companies have stable waste streams that remain consistent day to day, on-site systems are more capable of operating efficiently and delivering reliable throughput.

- Organizations seeking internal energy recovery: On-site organic waste processing is ideal for companies that want to use outputs within their own operations. For example, biogas from anaerobic digestion can generate electricity to power internal processes.

- Multi-year sustainability commitments tied to internal processing: On-site systems support organizations with long-term sustainability goals that require direct control over waste reduction efforts. Internal processing enables clear tracking of progress and measurable, year-over-year results toward these commitments.

- Long-term ROI potential for very high-volume generators: Although on-site infrastructure requires a high upfront investment, companies that generate very large volumes of waste may benefit financially over time by reducing hauling costs and capturing value from outputs.

Investment & Operational Requirements

Now let’s answer the question we’re all wondering: What are the investment requirements for on-site food waste processing?

Here’s a quick overview:

- CapEx purchase

- Installation and commissioning

- Maintenance cycles

- Lifecycle cost

- Equipment replacement windows

- Internal compliance responsibility

Unsure whether your facility has the volume, staffing, and footprint for on-site processing? Shapiro will help you evaluate your options based on real data.

Option 2: Off-Site Contracted Organic Waste Processing

Now that we’ve covered the complexities of on-site waste management, let’s take a look at off-site processing.

Why Most Facilities Choose Off-Site Processing

Many companies that generate food waste opt for a third-party food waste recycling service due to its efficiency, cost-effectiveness, and, let’s face it, its ability to take the headache out of the entire process.

The advantages of off-site commercial composting and anaerobic digestion include:

- No CapEx

- Minimal operational burden

- Faster implementation

- Access to multiple AD/compost outlets

- Predictable OpEx costs

- Easier compliance

- Resilience during volume surges or recalls

- Reduced contamination and load-rejection risks

Where Shapiro Fits In

For facilities that choose off-site processing, selecting the right partner is critical.

Shapiro handles everything from composting waste management to liquid waste disposal and biochar solutions. With a deep understanding of the complexities of food waste management, we create tailored solutions that ensure cost-effective organic waste processing and compliance.

As part of our services, we offer:

- National access to organics processing outlets

- Ability to manage feedstock for digesters

- Multi-facility logistics

- Audit-ready documentation and chain of custody

- Certificates of Destruction

- Support for compliance, ESG reporting, and waste diversion metrics

Interested in an off-site program aligned with your operational and compliance needs? Contact Shapiro for tailored support.

Business Benefits of Each Path

On-site vs. off-site organic waste processing: what are the benefits of each option?

Let’s find out:

Operational Benefits

On-Site Management

- Reduced hauling: One of the benefits of on-site processing is that you don’t need to haul your organic waste to off-site commercial composting facilities, thereby minimizing disruptions tied to pickup schedules.

Off-Site Management

- Minimal maintenance burden: When you work with an external partner, you don’t have to worry about monitoring systems or providing regular maintenance.

- Fewer rejected loads: Waste management partners like Shapiro have extensive experience managing different waste streams and overcoming potential obstacles, resulting in fewer rejected loads.

- Cleaner outbound streams: Professional sorting and advanced facility technology help produce higher-quality outputs with improved contamination control.

- Better service continuity: Experienced waste management companies ensure adequate resources and have plans in place to address potential disruptions, leading to smoother workflows.

Financial Benefits

On-Site Management

- CapEx ROI: Investing in on-site waste processing can be beneficial due to its ability to reduce long-term disposal and transportation costs. Even more, companies that turn the outputs into a new revenue stream, such as compost or bioenergy, can increase their bottom line.

- Reduced landfill and hauling fees: With landfill disposal costs rising, avoiding these fees is a significant financial benefit of on-site organic waste processing.

- Avoidance of surcharges: By handling waste at the source, businesses can avoid common surcharges tied to contamination, overflow, or transportation delays. We should note, though, that this is also possible when working with an experienced provider, as their increased efficiency helps prevent the issues that trigger these surcharges.

Off-Site Management

- Predictable OpEx: Off-site partnerships offer more predictable operating expenses, meaning companies don’t have to worry about unexpected costs related to equipment or employee training.

- Lower contamination penalties: Waste management professionals use specialized processes and equipment to sort, store, and manage waste, reducing the chance of contamination penalties.

Environmental & Compliance Benefits

When it comes to environmental and compliance benefits, we don’t prefer to differentiate them as a benefit of either on-site or off-site. Why?

Because both processes can lead to long-term environmental benefits if performed correctly. This includes:

- Methane reduction

- Alignment with organic waste bans

- Traceability and audit readiness

- ESG reporting improvements

- Higher diversion rates

In general, we’d say these benefits are more often associated with off-site management, as specialists have the training needed to ensure optimal environmental outcomes. However, a well-organized on-site program can also achieve them.

What’s important is that the leaders of each program are up to date with best practices and compliance requirements to achieve the best results.

Want to learn more about organic waste processing? Check out our food waste recycling guide.

How to Evaluate the Right Path for Your Facility

Before choosing between on-site and off-site organic waste processing, consider the following:

- Volume and load profile assessment: You should consider how many tons of waste your company produces each month, the consistency of your waste stream, your level of contamination and ability to manage it, and any special packaging processes required.

- Cost-benefit factors: Companies should compare current spending with the potential costs of on-site operations or working with an external partner. Since on-site systems have large upfront costs, working with a partner is usually more feasible, yet every company must consider its unique resources.

- Regulatory & ESG requirements: State-specific bans, corporate sustainability goals, and customer or retailer expectations are all key considerations. Is your company prepared to follow all compliance requirements on-site, or do you require external expertise? This is an important question to consider.

- Implementation timeline expectations: Every company must consider its unique timing needs. On-site systems take time to set up, train employees, and become operational, while partner-based processes can start as soon as the contract is signed.

What to Look for in an Off-Site or On-Site Partner

Whether you opt for external processing or want to implement an on-site program, here are the qualities to look for when working with a specialist who supports your chosen approach:

- Technical capabilities: You should evaluate the certifications, processing technologies, and contamination tolerance of your waste management partner. If you choose on-site waste management, ensure you have trained personnel who know how to handle it.

- Geographic coverage and logistics: Waste management specialists that offer multi-facility and multi-state support are better equipped to manage peak loads or disruptions. At Shapiro, we have a nationwide network that helps us service even the most remote locations, making us a reliable partner for all your organic waste management needs.

- Documentation and compliance support: We recommend choosing a partner that assists with documentation and compliance, including support with Certificates of Destruction, chain-of-custody, and ESG-ready reporting.

Final Thoughts

Whether you’re interested in business composting, biogas production through anaerobic digestion, or another innovative waste reduction solution, your company should evaluate the pros and cons of on-site vs. off-site organic waste processing.

At Shapiro, we have over 30 years of experience as a waste management provider. Our expertise helps you achieve sustainability goals while ensuring compliance, reducing costs, and lowering your environmental impact.

Contact us today to learn more about our organic waste processing solutions.

FAQs about Organic Waste Processing

On-site processing treats organic waste directly where it’s produced, while off-site processing involves transporting it to an external partner for handling.

On-site composting can be cheaper over time if your volume is high enough to offset the upfront capital investment and operational requirements. That said, off-site processing is usually more affordable because it avoids large upfront costs and ongoing maintenance demands.

Consistent daily or weekly waste generation in sizable quantities is needed for on-site processing, so a volume assessment is key to determining feasibility.

On-site systems carry risks such as equipment downtime, contamination management, maintenance demands, and compliance responsibilities.

Off-site processing is ideal when your facility lacks the space, staffing, capital, or consistency needed to operate an on-site system reliably.

Most on-site composting or AD systems require state or local permits, depending on system size, waste type, and regulatory requirements.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.