Oil plays a pivotal role in powering our daily lives. But what happens to oil once it has served its purpose? Often, it’s disposed of, and although this disposal is necessary, it’s not without significant environmental costs. The improper handling of oil can lead to pollution, contamination of water sources, and long-term damage to ecosystems.

Enter oil recycling – a solution that transcends the traditional disposal methods. By recycling oil, we’re not merely discarding a used product; we’re breathing new life into it. It offers a pathway to avoid the disadvantages associated with oil disposal, turning potential waste into valuable resources. It’s a process that promotes a sustainable circular economy where used oil is treated, transformed, and repurposed for various applications.

Key Takeaways

- Understanding Oil Recycling: Oil recycling involves repurposing, treating, and transforming disposable oil into valuable by-products for various industries.

- Importance and Benefits: Recycling oil promotes sustainability, reduces environmental impact, and supports various industries like farming and agriculture.

- Types and Processes: Various techniques such as reconditioning, refining, burning, filtering, and distillation are involved in oil recycling.

- Recyclable Oil Sources: Different sources like food, engine, restaurant, vegetable, and mineral oils can be recycled.

- Entities Involved: Generators, collection centers, transporters, re-refiners, burners, and marketers play key roles in handling recyclable oil.

- Regulatory Compliance: Adhering to regulations is crucial to avoid legal and financial consequences.

- Professional Assistance: Certified companies like Shapiro offer specialized expertise and services to ensure responsible and effective oil recycling.

What is oil recycling?

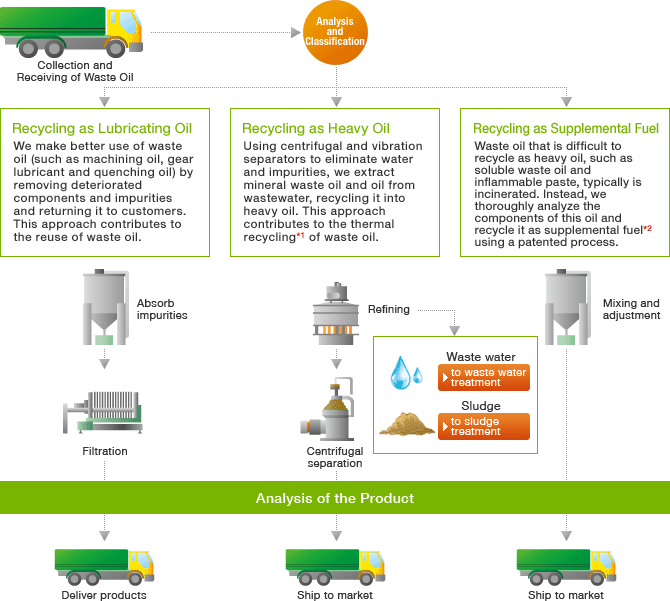

Oil recycling is a vital process that involves repurposing, treating, and transforming disposable oil into reusable by-products. This includes re-refining used oil into lubricants, processing it into fuel oils, and utilizing it as raw materials in various industries such as farming, agriculture, cosmetics, and energy. Recyclable oil, as defined by the EPA, must meet specific criteria related to its origin, use, and contaminants. By recycling oil, we not only reduce waste but also contribute to a sustainable and environmentally friendly approach to resource management.

Why does oil recycling matter?

Recycling oil has a profound impact on our world, touching various aspects of our lives. Here’s why it holds such significance:

- Environmental stewardship: protecting the environment is at the heart of oil recycling. By giving used oil a new purpose, we keep harmful substances from contaminating our earth and water. It’s a conscious decision to care for the planet we call home.

- Economic efficiency: recycling oil makes financial sense too. It reduces the demand for new oil, leading to a more efficient use of resources and a positive impact on the bottom line.

- Supporting sustainability: in the broader context of sustainability, the recycling of oil fosters a circular economy. This approach ensures that resources are used to their fullest potential, promoting long-term ecological balance and responsible growth.

Types and processes of oil recycling

Recycling oil is a complex process that involves various techniques, each serving a unique purpose.

1. Reconditioning

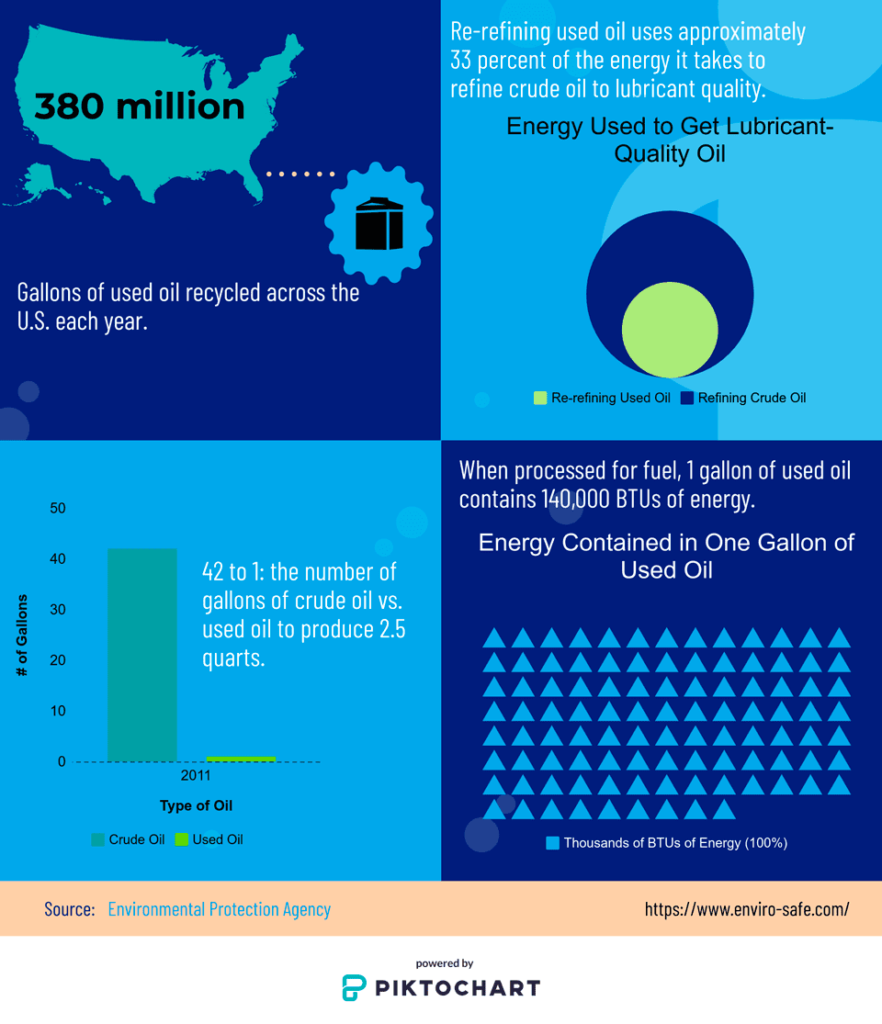

Reconditioning is a viable alternative to replacing used oil, and it involves various physical, chemical, and combined methods. Physical methods include settling, centrifuging, filtration, heating, and evaporation, while chemical methods may involve acidic and alkaline treatment or hydrogenation. Combined methods like coagulation, adsorption, ion exchange, and extraction lie between physical and chemical processes. The selection of a specific process depends on how the oil changes during use. Reconditioning can extend the life of oil significantly, consuming only one-third of the electric power required to make the same amount of oil from crude.

2. Refining and re-refining

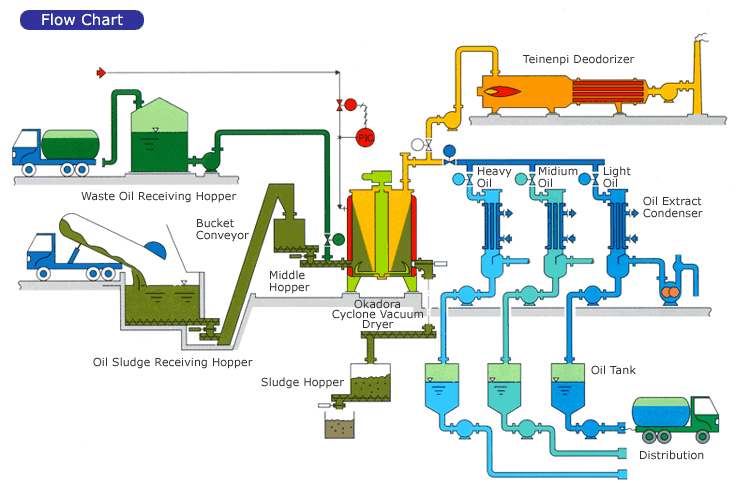

Refining and re-refining are processes that transform used oil into new products. It involves separating the oil into different fractions through distillation, followed by chemical treatment to remove impurities. Re-refining, on the other hand, is a more intensive process that further purifies the oil, producing high-quality base oils for lubricants and other applications. These methods contribute to resource efficiency by turning waste oil into valuable products.

3. Burning

By converting oil into heat or electricity, this process utilizes a resource that might otherwise be wasted. It’s an approach that aligns with energy conservation goals and supports broader sustainability efforts. This serves as a practical solution that reduces waste, minimizes environmental impact, and provides a renewable energy source.

4. Filtering and demineralization

Filtering and demineralization are processes that purify used oil by removing solids and minerals. It involves passing the oil through membranes or other filtration systems to extract particles and impurities. Demineralization takes it a step further by using ion exchange or other chemical processes to remove dissolved minerals. These techniques result in cleaner oil that can be reused in various applications, enhancing its value, and reducing its environmental impact.

5. Distillation

Distillation is a fundamental process in oil recycling that separates the oil into different components based on their boiling points. It involves heating the oil to vaporize it and then condensing the vapors into liquid fractions. The fractions are collected separately, allowing for the isolation of specific products such as lubricants, waxes, and fuels. Distillation is a versatile method that can be adapted to various types of oils, providing flexibility in recycling and product development.

Recyclable oil sources and examples

Recyclable oils come in various forms, each with unique characteristics that make them suitable for recycling. Understanding these sources and their properties is essential for effective recycling and waste management.

- Cooking oil: the disposal of cooking oil entails collection, filtering, and processing to remove impurities. The refined product can then be used in the production of biodiesel or even animal feed. The ability to remove contaminants and the presence of reusable compounds make this type of oil suitable for recycling.

- Engine and hydraulic oil: including motor oil and transmission fluid, it can be re-refined and reused. The recycling process involves removing contaminants like dirt and metal particles. The recyclable nature of these oils is due to their stable base oil composition, which can be purified and reutilized.

- Vegetable oil: used in various industrial applications, it can be recycled through processes like filtration and purification. The inherent biodegradability and renewable nature of vegetable oils make them suitable candidates for recycling.

- Mineral oil: often used in industrial applications and cosmetics, it can also be recycled. Its non-biodegradable nature requires specialized processing to remove impurities and contaminants. The recycled mineral oil can then be used in various applications, such as lubrication and energy production. This recycling process emphasizes the importance of proper handling and treatment to ensure that the oil can be reused effectively.

What entities participate in handling recyclable oil?

The journey of recyclable oil from its origin to its renewed purpose involves a network of specialized entities. Each plays a distinct role in ensuring that used oil is handled with care, efficiency, and responsibility.

Generators

Generators are businesses and individuals engaged in commercial or industrial operations that handle used oil. They are the largest segment in the used oil industry and include car repair shops, service stations, metalworking industries, and boat marinas. However, farmers producing less than 25 gallons of used oil per month and individuals maintaining personal vehicles are generally excluded from this category.

Collection centers and aggregation points

These facilities, often referred to as oil recycling centers, accept small quantities of used oil and store it for recycling. Collection centers receive oil from various sources, including businesses and individuals, while aggregation points collect oil from places run by the same owner or operator.

Transporters

Transporters are companies responsible for oil recycling pickup. They collect used oil from all sources and deliver it to re-refiners, processors, or burners. This category also includes transfer facilities where used oil is held temporarily before being transported.

Re-refiners and processors

Re-refiners and processors, often operating within an oil recycling facility, blend or remove impurities from used oil for energy recovery or reuse. This category includes those who process used oil into new products, such as lubricants, enabling continuous recycling.

Burners

Burners utilize used oil for energy recovery in various devices, such as boilers and industrial furnaces. They play a vital role in converting waste into valuable energy resources.

Marketers

Marketers are handlers who direct shipments of used oil for energy recovery or claim compliance with specific EPA specifications for burning used oil. They may also facilitate the movement of used oil to burners and often fall into one or more of the above categories.

Oil recycling regulations

The regulatory landscape for oil recycling is complex and demands careful attention to detail. Non-compliance can result in significant financial and legal consequences. Businesses must invest in proper training, equipment, and processes to ensure that they meet all regulatory requirements. By doing so, they not only protect the environment but also safeguard themselves from potential legal and financial risks.

Some regulations, requirements, and precautions include:

Requirements for Storing Used Oil:

- Containers and tanks must be labeled as “Used Oil.”

- They must be kept in good condition, and any structural defects must be fixed immediately.

- Used oil must be stored in specific oil recycling containers.

- Storage in unpermitted areas is prohibited.

Requirements for Oil Leaks and Spills:

- Preventive measures must be taken to avoid leaks and spills.

- In case of a spill, immediate action must be taken to stop the flow, contain the oil, and clean up the spill.

- Defective tanks or containers must be repaired or replaced immediately.

Standards for Record Keeping:

- Specific identification numbers are used to track used oil.

- Records of each acceptance and delivery of used oil shipments must be maintained for three years.

- Secondary containment systems are encouraged to prevent contamination.

Hazardous Waste Considerations:

- Mixing with Hazardous Waste: If used oil becomes contaminated with hazardous liquid waste, it must comply with federal and state hazardous waste regulations.

- Exemptions: Certain used oil filters are excluded from regulation as RCRA hazardous waste if they are hot-drained.

Implications and Challenges

Non-compliance with these regulations can lead to:

Environmental Impacts:

- Spills or leaks can contaminate soil and water, leading to costly cleanup and potential harm to wildlife.

- Long-term environmental damage may result in ongoing monitoring and remediation expenses.

Operational Challenges:

- Implementing the necessary procedures, training, and equipment to comply with regulations can be time-consuming and costly.

- Constant updates to regulations require ongoing vigilance and adaptation.

Reputational Damage: Non-compliance can lead to negative public perception, potentially affecting customer trust and business relationships.

Fines and Penalties: Non-compliance can result in hefty fines and legal penalties, which can significantly impact a company’s bottom line.

Cleanup Costs: Spills or improper disposal can lead to extensive cleanup costs, including soil remediation and water treatment.

Increased Operational Costs:

- Compliance requires investment in proper storage, handling, and disposal equipment, as well as continuous training and monitoring.

- Regular audits and inspections may be necessary to ensure ongoing compliance.

Legal and Litigation Expenses: legal challenges or lawsuits resulting from non-compliance can lead to substantial legal fees and potential settlement costs.

Potential Loss of Business: failure to comply with regulations may lead to the loss of necessary permits or certifications, hindering the ability to operate in certain jurisdictions or industries.

How can oil recycling companies help?

As we can see, the stakes are high when it comes to oil recycling and disposal, as mistakes can lead to legal issues, environmental damage, and financial loss. This is why the task is better left to certified professionals who understand the intricacies of the process.

With a deep understanding of the regulations, state-of-the-art equipment, and a commitment to environmental responsibility, such a company ensures that oil recycling is done right. It minimizes risks, maximizes resource utilization, and contributes to sustainability, all while adhering to the highest industry standards.

Conclusion

Oil recycling is more than a mere industrial process; it’s a vital component of our collective responsibility towards the environment and future generations. The journey from used oil to valuable by-products is filled with complexities, regulations, and opportunities. It’s a path that demands expertise, integrity, and a vision that transcends mere profit. By embracing responsible oil recycling practices, we not only conserve precious resources but also contribute to a sustainable circular economy that benefits us all. The choices we make today in handling and recycling oil will resonate far into the future, shaping the legacy we leave behind. It’s a challenge, a commitment, and an opportunity to make a real difference.

At Shapiro, we take these responsibilities to heart in our liquid waste services. Our team of experts is committed to providing top-notch oil recycling solutions tailored to your needs. With Shapiro, you’re not just choosing a service provider; you’re partnering with a trusted ally in responsible and effective recycling and disposal. Trust us to make the process seamless, compliant, and environmentally sound.

Frequently Asked Questions

Yes, oil can be recycled. Through various processes such as reconditioning, refining, re-refining, burning, filtering, and distillation, used oil can be transformed into valuable products like lubricants, fuel oils, and raw materials for various industries. Recycling oil not only conserves resources but also minimizes its environmental impact.

Used oil is recycled by specialized recycling facilities, industrial plants, and automotive service centers. Some municipalities also offer recycling programs for certain types of oil. Various businesses and industries that utilize large quantities of oil may have their own recycling processes or partner with professional recycling services, like Shapiro.

Oil can be recycled at designated recycling centers, automotive shops, and sometimes at local waste disposal facilities that accept used oil. Many cities and towns have specific locations where residents can drop off used oil for recycling. It’s advisable to check with local authorities or search online for nearby recycling locations that accept the specific type of oil you have. Alternatively, by partnering with a professional oil recycling company like Shapiro, we will come to you and collect any recyclable oil.

Oil is recycled through a series of processes that may include:

Collection: Gathering used oil from various sources.

Filtration: Removing solid contaminants and impurities.

Dehydration: Eliminating water and moisture content.

Distillation: Separating different components based on boiling points.

Treatment with Additives: Restoring or enhancing specific properties.

Quality Testing: Ensuring the recycled oil meets the required standards.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.