Bakeries, with their delightful, freshly baked goods, are a source of joy for many. Yet, behind the scenes, they also churn out a significant amount of waste.

From the remnants of bread loaves to cake scraps, the discarded bits can quickly add up.

For example, did you know that about one third of food waste (equal to 830 million tons) generated annually occurs at the production stage?

However, this waste isn’t simply destined for the landfill. With the right practices in place, much of it can be disposed of responsibly or even recycled.

But how can bakery businesses achieve this?

Let’s explore all about bakery waste, its generation trends, utilization methods, and some useful waste management practices.

Key Takeaways

- The primary contributors to bakery waste generation are unsold products, dough, and ingredient remnants.

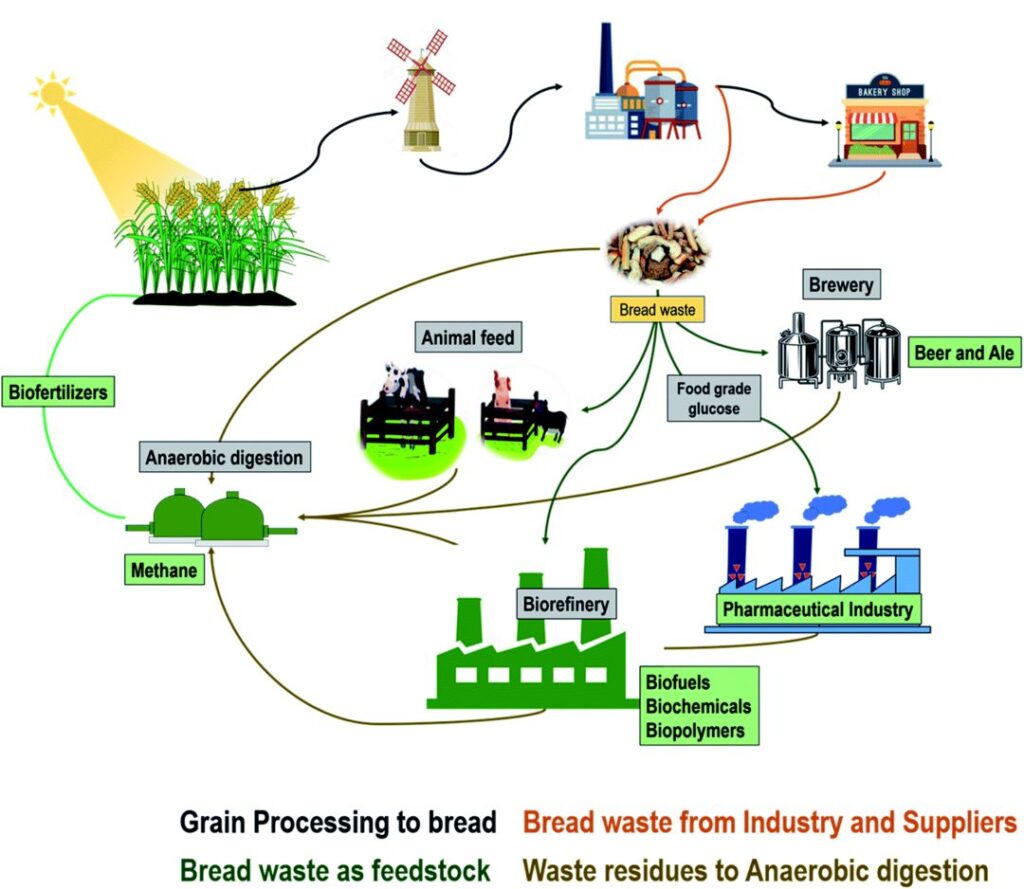

- Utilization of bakery waste can take many forms, from repurposing as animal feed to upcycling for industrial applications.

- Effective treatment of bakery wastewater involves pre-treatment processes and advanced techniques like acidification.

- The bakery waste management landscape is evolving with emerging technologies, offering sustainable solutions to reduce waste and promote eco-conscious practices.

Understanding Bakery Waste

Bakery waste is a diverse mix of organic and inorganic materials, primarily composed of leftover or unsold baked goods.

This waste is generated at various stages of the baking process, from food preparation to post-production. For instance, misshaped or overcooked pastries often end up as waste, as do expired ingredients.

Let’s delve deeper into the composition and generation of bakery waste:

Bakery Waste Composition

Bakery waste is a complex mixture of materials, each with its own characteristics and challenges for disposal. The primary components of bakery waste include:

- Unsold baked goods: This category encompasses bread, pastries, cakes, and other baked goods that have exceeded their shelf life or have slight imperfections, rendering them unsuitable for sale.

- Dough and batter residues: Leftover dough and batter from the baking process contribute to waste. These residues may result from overproduction, recipe adjustments, or trimming excess dough during shaping.

- Ingredients: Bakery waste includes expired or spoiled ingredients like flour, sugar, eggs, milk, and various flavorings. These components are integral to the baking process but can become waste if not managed efficiently.

- Packaging materials: Contaminants like plastic, cardboard, and paper from packaging materials may also find their way into bakery waste.

Generation of Bakery Waste

The generation of bakery waste occurs at various stages of production, including:

- Ingredient preparation: The journey of bakery waste begins with the preparation of ingredients. This includes measuring, mixing, and handling flour, sugar, eggs, and other raw materials. Waste can accumulate at this stage due to spillage, over-measuring, or the spoilage of ingredients over time.

- Baking and production: Imperfections in baked goods, overproduction, and irregular shapes may render products unsuitable for sale. This often results in the disposal of unsold or subpar items.

- Trimming and shaping: Bakers often trim excess dough to create uniform shapes and sizes. While necessary for product consistency, this process generates additional waste.

- Expiration: Many bakery products have relatively short shelf lives. So, when they exceed their sell-by or use-by dates, they become waste.

- Packaging: Packaging materials like plastic bags, cardboard boxes, and paper wrappers can contribute to bakery waste if not disposed of correctly.

Bakery Waste Utilization

The good news?

Bakery waste doesn’t have to end up in landfills.

There are practical steps that you can take to manage and reduce your waste, contributing to a more sustainable and environmentally friendly operation. Here are some ways in which bakery waste can be repurposed or recycled:

- Contribute to local communities: Rather than discarding your unsold baked goods, you can donate surplus items to your local food banks. Not only does this support the community, but it also benefits your bakery. Food donations can reduce your trash hauling costs, and you may even qualify for federal tax deductions related to food donations.

- Avoid single-use items: To further reduce costs and waste, you can eliminate single-use items like plastic cups, straws, and disposable bottles. This not only decreases trash volume and expenses but also enhances the overall customer experience.

- Recycle: Cardboard, aluminum cans, plastic, and glass bottles are all recyclable materials. By enrolling in cardboard and single-stream recycling programs, you can significantly reduce waste and associated costs.

- Compost: Did you know that paper towels, napkins, and food scraps can all be composted? Bakeries practicing composting have not only reduced waste but also improved internal food procurement and handling processes, leading to cost savings.

Bakery Waste as Animal Feed

Converting food waste to animal feed is a great way to reduce waste. This usually happens through anaerobic digestion (the decomposition of organic waste in the absence of oxygen).

There are a few bakery waste types that can be converted into animal feed. For example:

- Pastry and bread waste: Bakery products that haven’t found their way to customers can often serve as excellent animal feed. Stale or unsold bread, as well as pastries nearing their shelf life, can be repurposed as feed for chickens, pigs, and other animals.

- Dough: Excess or leftover dough is another candidate for animal feed. It provides a source of carbohydrates and can be especially suitable for livestock.

- Trimming and scraps: The trimmings and small scraps generated during the preparation of baked goods are usually not suitable for human consumption. But they can be valuable additions to animal diets.

Using bakery waste as animal feed also offers several advantages like:

- Waste reduction

- Cost savings

- Nutrient recycling

- Supporting agriculture

- Reduced environmental impact of food disposal

Industrial Applications of Bakery Waste

Beyond its potential as animal feed, bakery food waste can be upcycled into new valuable resources and used in various industrial applications. Here are a couple of examples:

Fermentation

Industrial bakery waste, rich in carbohydrates and other organic compounds, can be a valuable substrate for fermentation processes. This involves the microbial conversion of organic matter into useful products like:

- Biofuels: The sugars and starches present in bakery waste can be converted into biofuels (such as ethanol) through fermentation. This repurposes bakery waste into an eco-friendly alternative to fossil fuels.

- Enzymes: Fermentation can produce enzymes used in various industrial applications, from food processing to detergents. Bakery waste can serve as a cost-effective source of raw materials for enzyme production.

Biopolymer Production

Bakery waste contains polysaccharides, proteins, and lipids that can be utilized in the production of biopolymers.

But what are biopolymers?

Biopolymers are biodegradable alternatives to traditional plastics and have a wide range of applications.

Using bakery waste in biopolymer production offers the following benefits:

- Sustainable packaging: Biopolymers derived from bakery waste can be used for sustainable packaging materials, reducing the reliance on petroleum-based plastics and minimizing environmental impact.

- Agricultural films: Biodegradable films produced from bakery waste-based biopolymers can be used in agriculture to enhance soil health and reduce plastic waste in farming.

Wastewater Management in Bakeries

Wastewater management in bakeries poses unique challenges due to the nature of their operations. Some of these challenges are:

- Organic load which can harm aquatic ecosystems

- High water temperatures which can endanger aquatic life

- Large volumes of wastewater which can overload treatment facilities

Characterization of Wastewater

Wastewater generated in bakeries is a complex mixture with high organic load. It contains ingredients such as:

- Flour

- Sugar

- Fats

- Food particles

These organic compounds pose challenges when present in wastewater due to their high biochemical and chemical oxygen demand levels.

Pre-Treatment of Bakery Wastewater

This crucial step ensures that the wastewater entering treatment facilities is in a condition that can be efficiently processed. Here are the main steps of this process:

- Screening: Screens or sieves are used to remove large debris, such as food particles, paper, and other solid materials. This prevents the solids from entering downstream treatment systems, reducing the risk of clogs and damage.

- Flow equalization: Bakery wastewater flow can vary significantly throughout the day. Flow equalization evens out these fluctuations, providing a consistent flow rate to treatment processes. This not only optimizes the efficiency of subsequent treatment steps but also helps avoid overloading the system during peak production times.

- FOG (fats, oils, and grease) separation: FOG can congeal and block pipelines, causing operational issues. Separation techniques, such as gravity settling or mechanical separation, are employed to remove FOG from wastewater, ensuring it flows smoothly through the treatment system.

Treatment Techniques for Bakery Wastewater

Managing bakery wastewater effectively involves employing specific treatment techniques to address its unique composition. Here are the key bakery wastewater treatment methods:

- Coagulation and flocculation: These chemical processes facilitate the removal of suspended solids and other impurities from bakery wastewater. Coagulants, such as aluminum sulfate or ferric chloride, are added to wastewater to destabilize particles. Then, flocculants (typically polymers) encourage these destabilized particles to form larger, easily removable flocs. This process significantly improves the clarity and quality of treated water.

- Acidification: Acidification is a pH adjustment process used to manage the alkaline nature of bakery wastewater resulting from ingredients like flour and yeast. By adding acids, the wastewater’s pH is lowered to a more neutral range, which is ideal for subsequent treatment processes. Acidification also helps in reducing the release of ammonia, a common issue in bakery wastewater.

Advancements in Bakery Waste Management

The bakery industry is experiencing a transformation in waste management, driven by a growing awareness of environmental sustainability and the emergence of innovative technologies.

Emerging Technologies

Emerging technologies are not only reducing bakery waste but also revolutionizing how bakeries operate. A few examples of such innovations are:

- Automated inventory management: Traditional inventory management systems often led to overstocking, resulting in excessive waste. Today, bakeries are turning to automated solutions that optimize ingredient procurement. These systems monitor ingredient levels in real time, ensuring that only the necessary amounts are ordered.

- Precision mixing equipment: Achieving the perfect consistency in dough and batter is crucial for bakeries. Precise mixing equipment minimizes ingredient wastage by ensuring accurate proportions and thorough mixing. This not only reduces raw material waste but also enhances product quality.

- Smart ovens: Smart ovens equipped with sensors and automation technology optimize the baking process. They adjust temperature and baking times, resulting in consistent product quality and reduced energy consumption. By eliminating batch-to-batch variations, smart ovens also help minimize product waste.

- Waste-to-energy systems: Some bakeries are taking sustainability to the next level by implementing waste-to-energy systems. These food waste technology systems convert bakery waste into usable energy, reducing the bakery’s carbon footprint.

Regulatory Framework

The food industry, including bakeries, operates within a framework of regulations aimed at promoting responsible waste management. Here are a few of the main regulations’ bakeries adhere to:

- Food safety regulations: Regulatory bodies like the Food and Drug Administration (FDA) in the United States and their counterparts worldwide set stringent standards for food safety. Compliance with these regulations not only safeguards consumers but also minimizes waste by preventing contamination and spoilage.

- Environmental regulations: Environmental agencies release guidelines for the proper handling and disposal of bakery waste. They encourage bakeries to reduce waste through recycling, composting, and responsible disposal methods to meet environmental compliance standards.

- Waste management regulations: Many regions have specific waste management regulations covering issues such as waste classification, collection, and disposal. These regulations often aim to minimize landfill waste by encouraging recycling and waste-to-energy practices.

- Sustainability standards: Various sustainability standards and certifications, such as ISO 14001, emphasize environmentally responsible practices. These standards often require bakeries to implement waste reduction and recycling programs, promoting eco-friendly operations.

Conclusion: A New Dawn for Bakery Waste Management

When it comes to bakery waste disposal and management, efficiency and sustainability are the keys to success.

If your bakery grapples with the challenge of responsibly managing waste, Shapiro is here to help. We offer expert advice and customized food waste recycling services.

Ready to embrace your greener future while enhancing your operational efficiency and environmental responsibility? Contact us today and learn how we can improve your bakery waste management process.

Baily Ramsey, an accomplished marketing specialist, brings a unique blend of anthropological insight and marketing finesse to the digital landscape. Specializing in educational content creation, she creates content for various industries, with a particular interest in environmental initiatives.